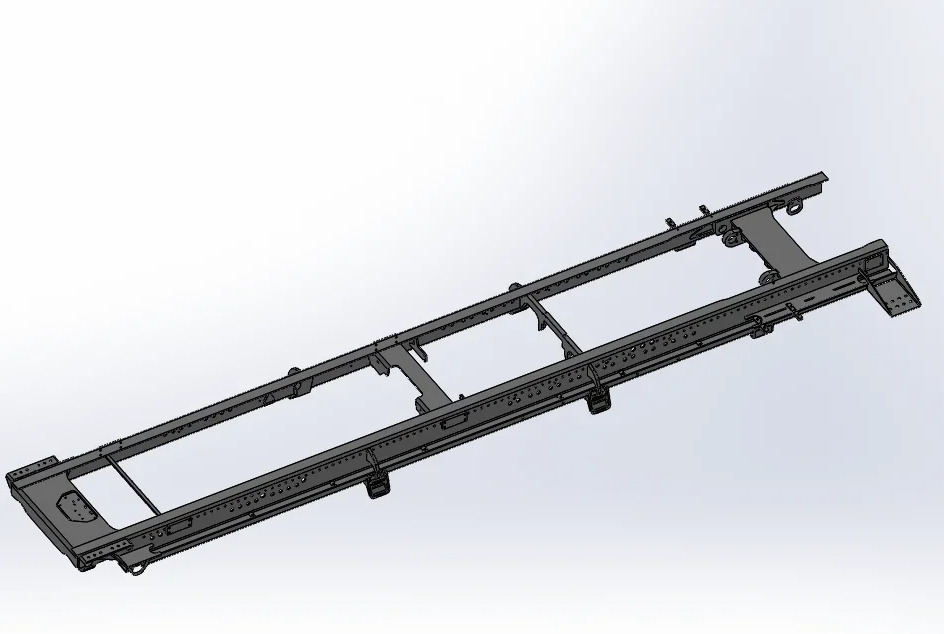

Selecting the right supplier for sub frame parts is a critical decision for manufacturers in the automotive, construction, agricultural, and special vehicle industries. Sub frame components are foundational to a vehicle’s structure, meaning that any compromise in quality or delivery can have serious consequences. At Hengli, we specialize in producing high-quality sub frame parts with advanced equipment and professional management, helping our clients achieve optimal performance, cost efficiency, and reliability.

Key Factors When Choosing a Sub Frame Parts Supplier

When evaluating suppliers, manufacturers should focus on four essential factors:

-

Quality – Precision in cutting, bending, welding, and machining ensures structural integrity and longevity.

-

Delivery Speed – Timely delivery avoids production delays and keeps projects on schedule.

-

Cost – Competitive pricing without sacrificing quality is critical for maintaining profit margins.

-

Service and Support – Technical consultation, customization, and post-delivery support enhance collaboration and product success.

Hengli addresses all these factors with its full metal supply chain integration, advanced machines, and extensive experience in sub-weldment manufacturing for lifting and heavy equipment.

Risks of Unreliable Suppliers in Vehicle Production

Partnering with an unreliable supplier can create serious risks:

-

Structural failures due to inconsistent welding or machining quality

-

Delays that affect production schedules and delivery commitments

-

Increased costs from rework, material waste, or non-compliance

-

Safety hazards for end users if components fail under load

Choosing a reputable supplier like Hengli minimizes these risks through rigorous quality control, precision manufacturing, and industry compliance.

How Hengli Balances High-Quality Production with Competitive Pricing

Hengli achieves a perfect balance between quality and cost through:

-

Advanced equipment for laser cutting, CNC machining, robot welding, and finishing

-

Efficient workflows that reduce waste and optimize production time

-

Expertise in working with diverse materials such as aluminum, steel, and titanium

-

Ability to provide specialized coatings and finishes to prevent corrosion and extend component life

This combination ensures that clients receive durable sub frame parts at competitive prices without compromising on quality or performance.

Customer Support and Technical Consultation Benefits

Beyond manufacturing, Hengli offers:

-

Technical consultation to optimize part design, materials, and finishes

-

Custom solutions for specialized applications in construction machinery, agricultural machinery, and vehicles

-

Assistance in coating, painting, and galvanizing processes to meet specific durability requirements

-

Dedicated support throughout the production and delivery process to ensure client satisfaction

Examples of Successful Partnerships and Satisfied Clients

Hengli’s proven track record includes:

-

Supplying high-precision sub frame parts for lifting equipment manufacturers with strict welding and machining standards

-

Partnering with automotive and agricultural machinery companies to deliver on-time, cost-effective solutions

-

Consistently maintaining low defect rates and meeting client specifications for custom finishes and coatings

These partnerships highlight Hengli’s commitment to quality, reliability, and client-focused service.

Conclusion

Choosing the right sub frame parts supplier is more than a procurement decision—it’s a strategic choice that impacts safety, performance, and profitability. Hengli’s advanced metal processing capabilities, comprehensive services, and experienced team make it a trusted partner for clients across construction, automotive, and industrial sectors. By combining precision, speed, and competitive pricing, Hengli ensures that your sub frame parts not only meet but exceed expectations.

www.hlmetal.net

Hangzhou Hengli Metal Processing Co.,Ltd.

+ There are no comments

Add yours