Have you ever thought about what gives flexible foams their softness or coatings their smooth finish? The secret often lies in polyether polyol, a crucial raw material used in the production of polyurethane products across various industries. From furniture and automobiles to construction and coatings, polyether polyol provides the foundation for materials that define comfort, durability, and performance.

Polyether polyol plays an essential role in modern material science due to its versatility and chemical stability. It reacts with isocyanates to produce polyurethanes — one of the most widely used polymers in the world. Whether used to create flexible foams, rigid insulation panels, or elastomeric coatings, polyether polyol delivers the balance between flexibility and strength that manufacturers rely on.

Understanding the Function and Types of Polyether Polyol

Polyether polyols are primarily derived from ethylene oxide (EO), propylene oxide (PO), or a combination of both. The molecular structure determines their characteristics — EO-based polyols offer greater hydrophilicity and reactivity, while PO-based ones provide superior flexibility and hydrolytic stability. By adjusting these ratios, chemists can design customized polyols for different industrial requirements.

The two main categories of polyether polyols include flexible polyols and rigid polyols. Flexible polyols are used to produce soft foams for upholstery, bedding, and automotive interiors, providing excellent cushioning and resilience. Rigid polyols, on the other hand, are key ingredients in high-density foams for insulation panels, adhesives, and protective coatings. Both types contribute to sustainability by enhancing energy efficiency and extending product life cycles.

Applications of Polyether Polyol Across Industries

The applications of polyether polyol are remarkably diverse. In the automotive industry, it is used for car seats, dashboards, and interior trim, where comfort and safety are equally important. In construction, it serves as the base for rigid polyurethane insulation boards that improve thermal performance and energy conservation in buildings. In furniture manufacturing, it gives mattresses, sofas, and cushions their signature softness and durability.

Beyond these, polyether polyol also finds its place in adhesives, sealants, and coatings, where it enhances bonding strength, elasticity, and surface smoothness. The use of polyether polyol in these formulations ensures better moisture resistance and mechanical properties, making it a preferred choice for both indoor and outdoor applications.

How to Choose the Right Polyether Polyol for Your Needs

Selecting the right polyether polyol depends on several factors, including molecular weight, functionality, and compatibility with other components in the formulation. For example, high molecular weight polyols are ideal for soft foams and elastomers, while low molecular weight types are better suited for rigid foams and coatings.

Buyers should also consider the viscosity and hydroxyl value, which affect the processing and final product performance. Working with a manufacturer that provides detailed technical specifications and formulation support can help ensure consistent results and long-term product reliability.

Jingfeng: A Reliable Source of Polyether Polyol Solutions

When it comes to sourcing dependable polyether polyol, Sichuan Jingfeng Advanced Materials Co., Ltd. stands out as a trusted partner. Established in 2020 and located in Suining City, Sichuan Province, Jingfeng specializes in the R&D, production, and sales of acrylic acid, ethylene oxide, and propylene oxide derivatives. The company’s product range includes hydroxyalkyl acrylate, polyethylene glycol (PEG), defoamers, methyl oleate ethoxylate, and polyether polyol — each engineered for consistent quality and industrial performance.

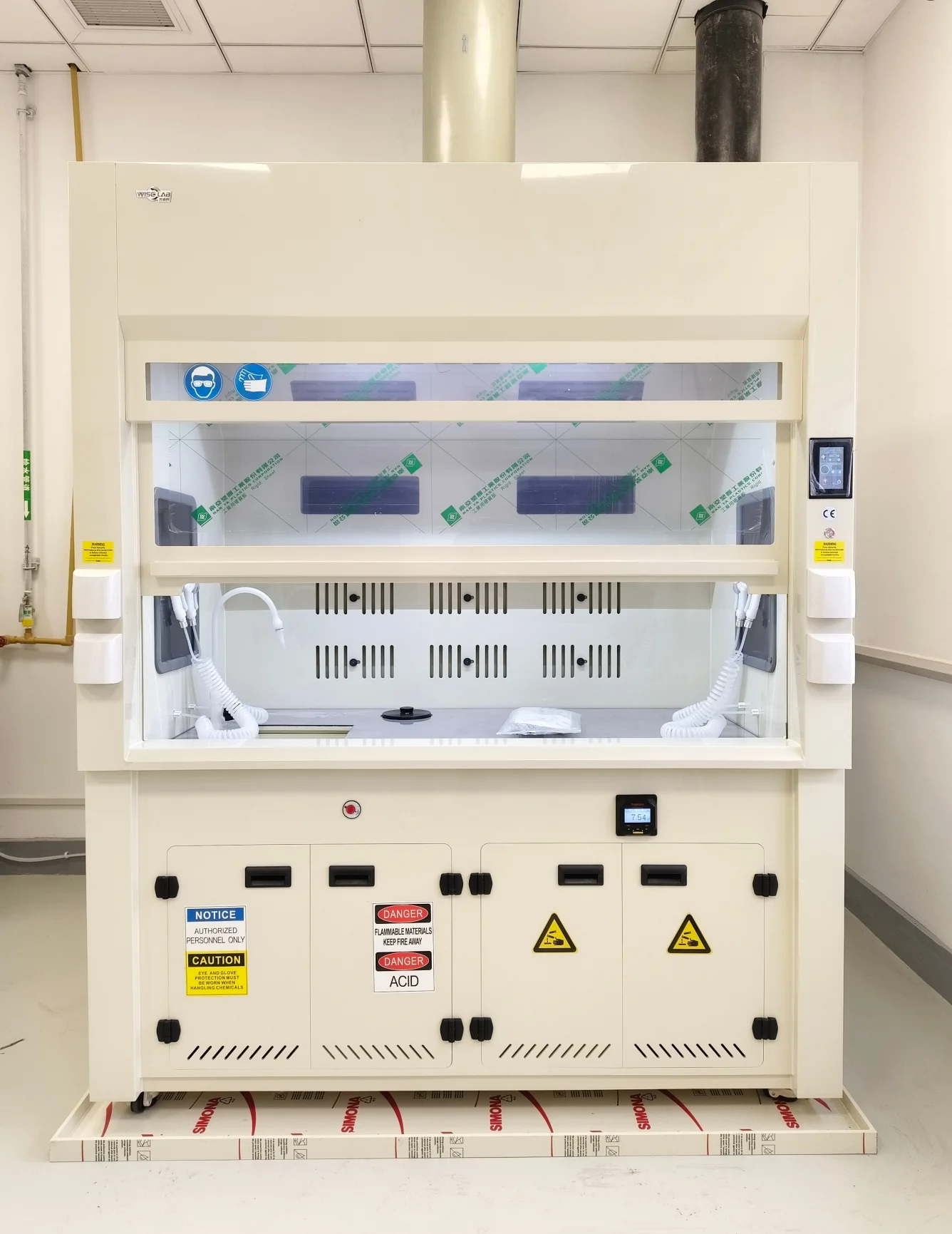

Cutting-Edge Manufacturing Technology

Jingfeng operates seven fully automated production lines equipped with advanced synthesis and purification equipment. These facilities enable precise control of polyether polyol molecular structure and functionality, ensuring optimal consistency and stability in every batch. The company’s production capacity reaches nearly 100,000 tons per year, allowing it to meet large-scale industrial demands efficiently.

Commitment to Quality and Customer Satisfaction

Quality remains at the heart of Jingfeng’s operations. Each product undergoes strict quality control, with every stage monitored from raw material selection to final packaging. The company adheres to international quality management standards and continuously upgrades its technology to enhance environmental safety and production efficiency. Jingfeng’s professional R&D team also works closely with clients to deliver customized polyether polyol solutions tailored to specific application requirements.

A Growing Global Partner in the Chemical Industry

With a customer-first philosophy, Jingfeng continues to expand its presence both in China and abroad. Its products are widely used in polyurethane manufacturing, coatings, and adhesives industries worldwide. The company’s mission — “Collaboration with Respect, Shared Success for All” — reflects its dedication to building long-term partnerships based on mutual growth and trust.

By combining advanced technology, stable supply, and personalized technical service, Jingfeng has established itself as a preferred polyether polyol supplier for companies seeking both reliability and innovation in material solutions.

Connect with Jingfeng for Polyether Polyol Supply

If you are searching for a dependable polyether polyol manufacturer, Jingfeng offers everything you need — from high-purity products and technical expertise to responsive customer service. Their comprehensive product line and strict quality assurance guarantee consistent performance for your polyurethane, coating, or adhesive applications.

Contact Sichuan Jingfeng Advanced Materials Co., Ltd. today to learn more about their polyether polyol products and other fine chemical materials. Let Jingfeng help you achieve better results, stronger materials, and more efficient production.

https://www.jinfonchem.com/water-reducing-agent-polyether-monomers.html

Jingfeng

+ There are no comments

Add yours