In modern HVAC projects, efficiency is no longer measured only by installation speed. It is defined by airflow performance, energy consumption, material utilization, and long-term system reliability. As HVAC contractors and manufacturers seek better ways to meet rising building standards, spiral duct production has become a clear preference over traditional rectangular ductwork. At the center of this shift is the spiral tube former, also known as a spiral duct machine.

A spiral tube former is specialized equipment designed to manufacture round spiral ducts used in heating, ventilation, and air conditioning systems. By transforming flat metal strips into rigid, airtight spiral ducts through continuous forming and locking, this machine significantly improves production efficiency while delivering superior duct performance.

Why Spiral Ducts Are Replacing Rectangular Ducts

Traditional rectangular ducts have been widely used for decades, mainly because they were easier to fabricate with older tools. However, they come with clear disadvantages: higher air resistance, more leakage points, greater material consumption, and higher noise levels.

Spiral ducts, on the other hand, are manufactured as round tubes with a continuous spiral seam. This structure provides several performance benefits:

-

Lower air resistance and improved airflow efficiency

-

Reduced pressure loss across long duct runs

-

Less vibration and noise during operation

-

Fewer joints and connection points, reducing leakage

-

Higher structural strength with thinner material

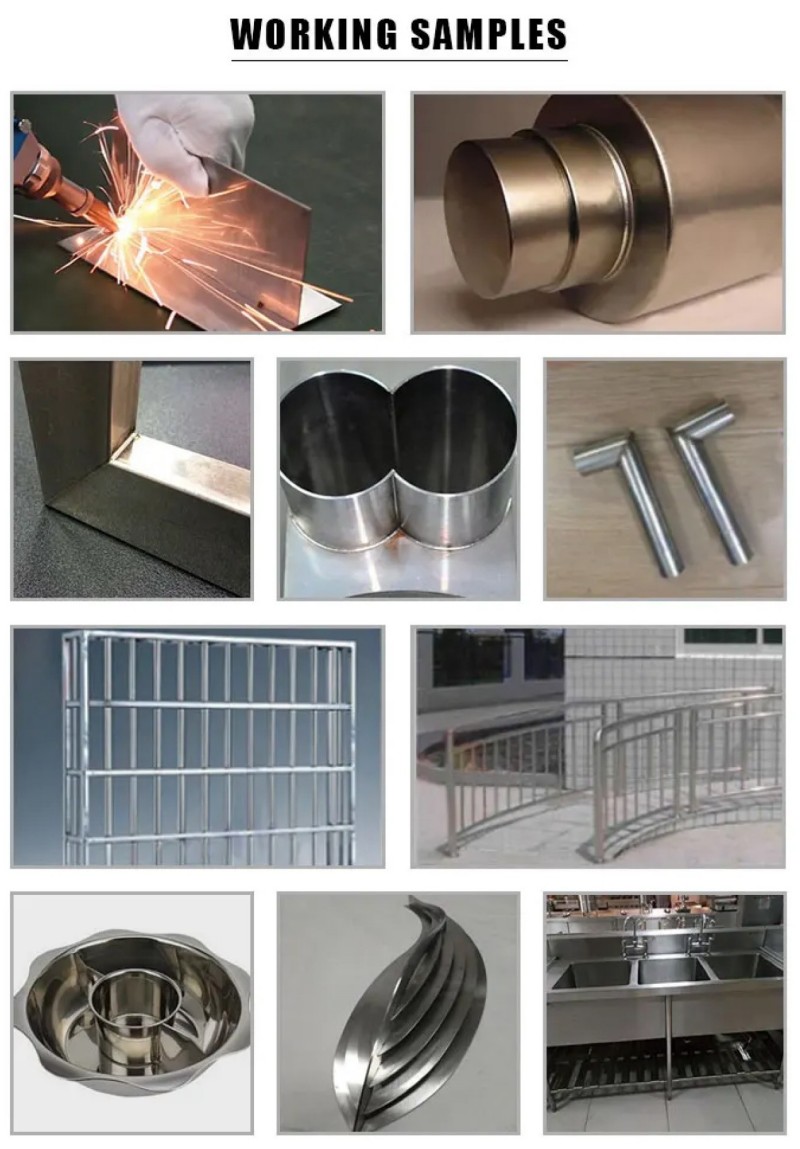

Because of these advantages, spiral ducts are now widely adopted in commercial buildings, industrial facilities, data centers, and large-scale ventilation projects.

How a Spiral Tube Former Works

A spiral tube former operates by feeding a metal strip—typically galvanized steel or aluminum—through a series of rollers. These rollers gradually form the strip into a round tube while simultaneously creating a spiral lock seam along the duct wall. This process requires no welding, eliminating heat distortion and reducing the risk of air leakage.

Once the desired length is reached, a high-speed synchronous cutting system cuts the duct cleanly and accurately. The result is a consistent, airtight spiral tube with a stable diameter and smooth interior surface.

This continuous production method is far more efficient than cutting, folding, and assembling rectangular ducts piece by piece.

Key Features That Improve Production Efficiency

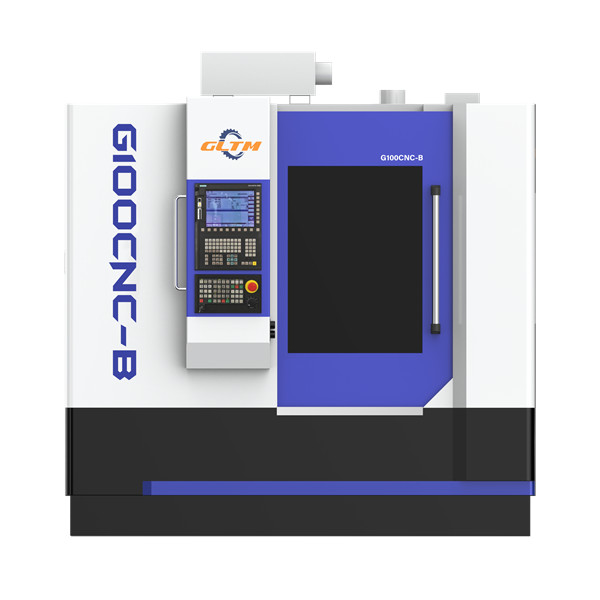

Modern spiral tube formers integrate advanced mechanical design and automation to maximize output and reliability. Spiral duct machines produced by Ma'anshan HeCheng Source Machinery Manufacturing Co., Ltd. are designed with long-term industrial use in mind and incorporate several efficiency-enhancing features.

Patented Adjustable Mold Design

The patented mold system allows operators to adjust duct diameters easily without extensive downtime. This flexibility enables manufacturers to produce a wide range of duct sizes using the same machine, minimizing changeover time and saving metal strip material.

Efficient material usage directly reduces production costs while maintaining consistent duct quality.

High-Speed Synchronous Cutting System

Accurate cutting is critical in duct manufacturing. The high-speed synchronous cutting system ensures clean edges and precise lengths, reducing the need for secondary processing and improving installation accuracy on-site.

PLC Control for Stable Operation

PLC-controlled operation ensures consistent forming pressure, seam quality, and diameter accuracy. Automation reduces reliance on manual adjustments, minimizes human error, and enables stable, repeatable production even during long operating hours.

On-Site Construction Capability

Spiral tube formers can be transported and operated directly at construction sites. On-site duct production reduces transportation costs, minimizes handling damage, and allows contractors to respond quickly to design changes.

This flexibility is especially valuable for large or complex HVAC projects where duct dimensions may need adjustment during installation.

Compatibility with Multiple Materials

The system can handle galvanized steel sheets and aluminum, making it suitable for various applications, from standard commercial HVAC systems to corrosion-resistant industrial environments.

Automatic Roll-Out and Diameter Adjustment

Automatic roll-out of equipment and adjustable diameter settings allow for smooth, continuous production of spiral tubes in different sizes. This capability supports both small-batch custom orders and large-scale standardized manufacturing.

Quality and Sealing Performance

One of the most important advantages of spiral duct machines is sealing performance. The spiral lock seam creates a tight, continuous joint that significantly reduces air leakage compared to traditional duct connections.

Better sealing means:

-

Lower energy losses

-

Improved indoor air quality

-

Reduced system load on fans and motors

-

Compliance with stricter energy-efficiency standards

High-quality bite formation and stable pipe diameter ensure that spiral ducts maintain their shape and performance over time, even under pressure fluctuations.

Impact on Overall HVAC Project Efficiency

Using a spiral tube former improves efficiency beyond the factory floor. The benefits extend throughout the HVAC project lifecycle:

-

Faster production: Continuous forming allows higher output with fewer labor hours

-

Simpler installation: Round ducts are easier to align and connect

-

Lower operating costs: Improved airflow reduces fan energy consumption

-

Reduced maintenance: Fewer joints mean fewer potential failure points

For HVAC contractors and system designers, these advantages translate into better project margins and more reliable system performance.

Supporting High-Quality Products and Services

Equipment quality is only part of the equation. Long-term productivity depends on stable machine performance, technical support, and reliable service. Spiral duct machines developed by Ma'anshan HeCheng Source Machinery Manufacturing Co., Ltd. are built with durability, ease of operation, and continuous innovation in mind, ensuring that manufacturers can meet both current and future HVAC market demands.

Manufacturers looking to expand or upgrade their spiral duct production lines can explore a full range of solutions through this spiral duct equipment lineup:

https://www.hcyhvacmt.com/Spiral-Duct-Machine

Conclusion

A spiral tube former is more than a duct-making machine—it is a productivity tool that reshapes how HVAC duct systems are manufactured and installed. By combining efficient material usage, high-speed automation, excellent sealing performance, and flexible operation, spiral duct machines help manufacturers and contractors achieve higher efficiency across the entire HVAC value chain.

As energy standards rise and project timelines tighten, investing in reliable spiral duct production technology is a practical step toward long-term competitiveness in the HVAC industry.

www.hcyhvacmt.com

Ma'anshan HeCheng Source Machinery Manufacturing Co., Ltd.

+ There are no comments

Add yours