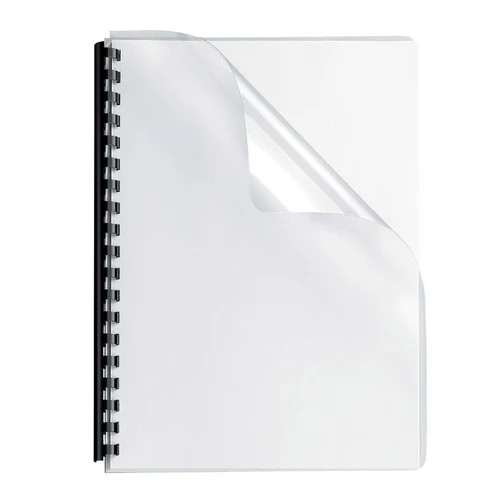

In modern office and document management, PVC binding covers have become an important document protection tool. Whether it is to save important documents in the enterprise or to keep learning materials in school, it provides good protection performance. However, there are many types of PVC binding covers on the market, and the quality is also uneven. How to distinguish the quality of A4 PVC binding covers has become a problem for many consumers. This article will analyze in detail how to distinguish the quality of A4 PVC binding covers by appearance, material, process, performance, etc., to help you make a more informed decision when choosing.

1. Key factors for distinguishing the quality of A4 PVC binding covers

When choosing A4 PVC binding covers, the following key factors are important criteria for judging their quality.

1.1 Material selection

Identification of high-quality PVC materials

The quality of PVC materials directly determines the durability of A4 PVC binding covers. High-quality PVC materials should have high transparency, smooth surface, and good compressive strength. High-quality PVC binding covers usually do not turn yellow, become brittle, or break.

Transparency: Transparent A4 PVC binding covers can clearly display the contents of the document. Poor-quality PVC covers may appear opaque or blurry due to impure materials or production process problems.

Smoothness: High-quality PVC binding covers have a smooth surface and no bubbles, and feel good when used; while low-quality products may have a rough surface, or even bubbles or creases.

Compression resistance: A4 PVC binding covers should have a certain degree of compression resistance, which can effectively protect documents from external pressure. If the PVC cover is too fragile and easily damaged, then its quality is not up to standard.

Environmentally friendly materials

With the improvement of environmental awareness, many consumers have begun to pay attention to the environmental friendliness of PVC binding covers. High-quality PVC covers use materials that meet environmental standards, usually marked with "no harmful substances" or "recyclable" and other logos. Poor-quality products may contain some ingredients that are harmful to the human body or the environment, so special attention should be paid when purchasing.

1.2 Thickness and durability

Choosing the right thickness

A4 PVC binding covers are available in different thicknesses, with common thicknesses of 0.1mm, 0.2mm, 0.3mm, etc. Generally, thinner covers are suitable for light documents, while thicker covers are suitable for heavy documents. High-quality A4 PVC binding covers should havean appropriate thickness, which can provide adequate protection without being too hard and brittle, resulting in easy breakage.

Elasticity of the material

High-quality A4 PVC binding covers have good elasticity and can maintain good shape during use. It is not easy to break or deform and is suitable for long-term use. Poor-quality PVC covers may be easily broken or creased due to lack of elasticity, affecting the use effect.

1.3 Processing and processing

Heat sealing process

The processing technology of A4 PVC binding covers directly affects its quality. The heat sealing process is a common packaging method. High-quality PVC covers should be even and flat when heat-sealed, without bubbles or incomplete heat sealing. Poor quality products may have uneven heat-sealed edges or even loose heat-sealed edges due to process problems, affecting the durability of the cover.

Edge processing

The edges of the A4 PVC binding cover should be flat and burr-free, especially since the heat-sealing process at the edges requires fine processing. If the edges are burred or improperly processed, the cover is prone to damage or tearing during use.

Printing quality

For A4 PVC binding covers that require custom printing, printing quality is also crucial. High-quality printed patterns should be clear, without color difference, and will not fall off due to friction or long-term use. Low-quality printing may cause color fading and blurring due to improper use of ink.

1.4 Performance in use

Waterproof performance

A4 PVC binding covers should have good waterproof performance, which can effectively prevent moisture penetration and protect the contents of documents from water damage. High-quality PVC materials can keep documents safe in humid environments, while poor-quality covers may cause moisture penetration due to poor waterproofness, affecting documents.

Dust and anti-fouling performance

The dust and anti-fouling function of the A4 PVC binding cover is also an important indicator for evaluating its quality. High-quality PVC binding covers can effectively prevent dust and stains from adhering, keeping the documents neat and tidy. Low-quality covers may be prone to dust and oil due to rough surfaces or uneven coatings, affecting the appearance.

Durability and compression resistance

The durability of A4 PVC binding covers directly affects the service life. High-quality covers can maintain stable performance during repeated reading and long-term use, while low-quality covers are prone to breakage, deformation, and even wrinkles or cracks. When purchasing, you can judge the durability of the cover by hand feel and bending tests.

1.5 Price and brand

Price is often proportional to quality. Although there are many low-priced A4 PVC binding covers on the market, the quality of these products may be problematic. Choosing a brand with a good reputation and credibility is usually more secure. Branded products often focus on quality control and the use of environmentally friendly materials, which can provide consumers with higher quality assurance.

2. How to choose high-quality A4 PVC binding covers?

Check the product material: Choose PVC materials with high transparency and good smoothness, and avoid choosing inferior materials.

Check the thickness: Choose the appropriate cover thickness according to the thickness of the document to ensure that it can provide adequate protection.

Pay attention to the processing technology: Make sure the cover edge is flat and the heat sealing process is uniform to avoid bubbles or poor heat sealing.

Check the waterproof and dustproof performance: Choose a cover with good waterproof and dustproof performance to ensure long-term protection of the document.

Choose a reputable brand: High-quality brands usually provide better after-sales service and product quality assurance.

As a key tool for document protection, the quality of PVC binding cover directly affects the security and service life of the document. Through the analysis of material selection, process processing, thickness, and performance, we can evaluate its quality more comprehensively. When purchasing, consumers should choose the appropriate A4 PVC binding cover according to their needs to ensure that their documents can be best protected.

www.mingyangindustrial.com

Hangzhou Fuyang Mingyang Industrial Co., Ltd.

+ There are no comments

Add yours