For mining, rare earth, gold, and R&D laboratories with limited space, the core appeal of spray-wash fume hoods lies in their robust corrosion-resistant exhaust gas treatment capability and flexible deployment. They can directly treat high-risk, highly volatile strong acid gases at the source, making them particularly suitable for scenarios where large external exhaust systems cannot be installed.

Below are key features for different industry clients:

? Mining Industry

· Core Benefit: Integrated, mobile on-site dust removal and air recirculation solution.

· Key Application & Value: Handles high-concentration dust and metal particles generated during tunneling and other processes. The mobile unit adjusts suction height to purify and recirculate air within enclosed spaces, improving underground working conditions.

? Rare Earth & Gold Smelting

· Core Focus: Specialized handling of highly toxic, radioactive, and high-value metal exhaust gases.

· Key Applications & Value:

· Rare Earth Smelting: Effectively captures and scrubs highly toxic corrosive gases like hydrogen fluoride, strong acid mists, and chlorine gas, while incorporating radiation protection. Actual procurement cases demonstrate this is essential equipment for the industry.

· Precious Metal Purification & Recovery: During acid digestion and purification processes, not only purifies exhaust gases but also recovers precious metal particles (e.g., gold) escaping with emissions, directly generating economic benefits.

? Residential/Roof-Top R&D Laboratories

· Core Highlights: The ultimate safety solution for high-risk strong acid experiments, eliminating the need for external large-scale scrubbing towers.

· Key Applications and Value:

· Eliminates explosion hazards completely: Specifically designed for explosive acids like perchloric acid. Through 360-degree spray rinsing inside cabinets and pipelines, it dissolves and removes acid mist condensates, eradicating explosion risks within pipelines.

· Efficiently treats highly corrosive gases: Completely dissolves and removes fumes from concentrated sulfuric acid, hydrofluoric acid, nitric acid, etc., via washing solution before discharge, protecting pipelines and the environment.

· Flexible installation, energy-efficient: Eliminates complex external exhaust piping and rooftop treatment towers. Operates independently, saving significant costs associated with air conditioning energy required to compensate for exhaust ventilation.

Common Core Advantages of the Product

Beyond the industry-specific benefits above, these units share several prominent advantages you can highlight based on your product features:

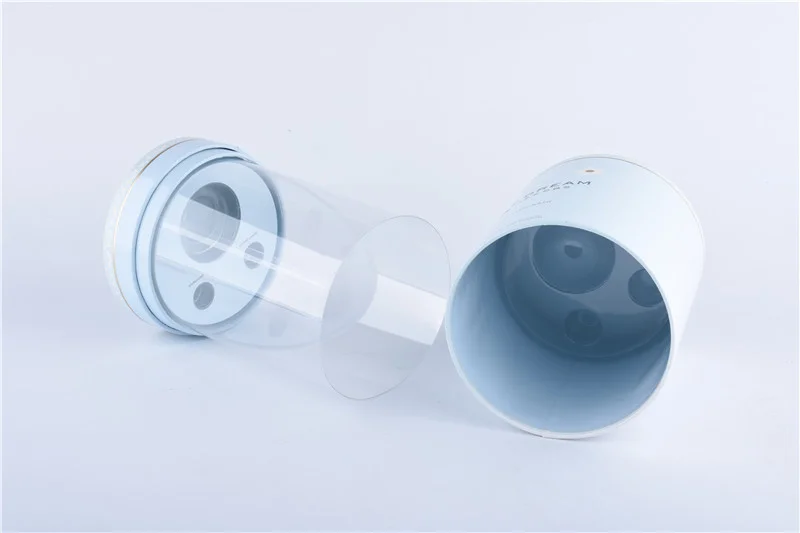

· Ultimate corrosion-resistant design: Cabinets, ductwork, and scrubbing systems are typically constructed from all-PP (polypropylene), PVC, or thermoplastic materials, ensuring complete resistance to strong acid corrosion from the inside out.

· Integrated Closed-Loop Safety System:

· Wash Solution Circulation & Neutralization: Wash solutions are reusable, with optional automatic pH adjustment systems to neutralize absorbed acids, minimizing waste discharge.

· Safe Waste Liquid Collection: Waste collection devices at the lowest points of fume hoods and ductwork ensure corrosive liquids are safely diverted and treated.

· Intelligent Monitoring and Management:

· Advanced models feature touchscreen controllers for real-time monitoring of fan status, filter saturation, and temperature/humidity. Alarms trigger promptly upon anomalies, enabling preventive maintenance.

How to Effectively Present to Clients

To help clients grasp the benefits intuitively, prepare materials from these angles:

· Prepare a comparison checklist: Create a table clearly contrasting “traditional exhaust ventilation systems” with “integrated spray-wash fume hoods” in terms of installation requirements, initial investment, safety risks, operating costs, and applicable scenarios.

· Highlight solutions: For residential lab clients, emphasize “specialized explosion-proof solutions for perchloric acid” or “pipeless strong acid experiment solutions” rather than merely listing equipment specifications.

· Present value cases: For rare earth and gold clients, emphasize dual benefits: “compliant exhaust emissions” and “precious metal recovery value.”

If you can provide specific product models or target client segments (e.g., prioritizing explosion safety or precious metal recovery), I can help refine more precise sales pitches and competitive strategies.

www.topairsys.com

Xinruiwei Semiconductor Technology (Suzhou) Co., Ltd.

+ There are no comments

Add yours