DIN 2413 hydraulic seamless pipe seamless is special for high-pressure hydraulic jobs because it is made very well and follows strict rules. Makers use top materials to give the pipe great strength and long life. In hydraulics, every part must work well. These pipes always work the same in hydraulic systems because they meet tough needs, like:

-

High strength to handle high hydraulic pressure and heavy loads.

-

Exact size for the best fluid flow in hydraulic systems.

-

Fights rust and temperature changes, so the pipe lasts longer.

-

Seamless build removes weak spots, keeping hydraulic work safe.

Hydraulic seamless pipe seamless always fits what advanced hydraulics need, helping hydraulic systems stay safe and work well in many industries.

Key Takeaways

-

DIN 2413 hydraulic seamless pipes do not have weld seams. This makes them stronger and safer for high-pressure hydraulic systems.

-

These pipes are made in different steel grades like E235, E355, and 1.4571. Each grade gives strength, durability, or corrosion resistance for different uses.

-

The strict DIN 2413 standards make sure pipes have exact sizes and strong materials. This helps hydraulic systems stop leaks and handle hard conditions.

-

Seamless pipes fight fatigue and corrosion better than welded pipes. This helps hydraulic machines last longer and work well.

-

Industries like automotive, aerospace, farming, and construction use these pipes for important parts. These parts include cylinders, valves, and pumps.

Key Features

Seamless Construction

Seamless hydraulic tubes are special because of how they are made. Makers heat a solid steel billet and push a hole through it. This makes a hollow tube with no weld seam. The tube is smooth and strong all the way through. There are no weak spots or places where stress can build up.

|

Aspect |

Seamless Pipes |

Welded Pipes (ERW) |

|---|---|---|

|

Made by piercing a solid steel billet to form a hollow tube without welding. |

Made by cold-forming steel coils into cylindrical shapes and welding the seam longitudinally. |

|

|

Structural Integrity |

Uniform, continuous structure without weld seams, eliminating weak points and stress concentrations. |

Contains a weld seam along the length, which can be a potential weak point and more susceptible to corrosion. |

|

Strength & Pressure |

Higher strength and pressure resistance due to absence of weld seam. |

Lower pressure suitability; weld seam requires extensive testing to ensure integrity. |

|

Appearance |

Smooth, consistent surface without visible seams. |

Visible weld seam along the pipe length. |

|

Typical Applications |

Preferred for high-pressure and high-temperature applications. |

More cost-effective; suitable for low to medium pressure applications. |

|

Testing Requirements |

Standard testing after production. |

Requires additional testing focused on weld seam integrity. |

Seamless hydraulic pipes can handle more pressure than welded pipes. They also last longer when used over and over. Welded pipes can have dents at the seam, which lowers their strength. Seamless tubes do not have this problem. That is why seamless steel pipes are best for high-pressure hydraulic work.

Material Grades

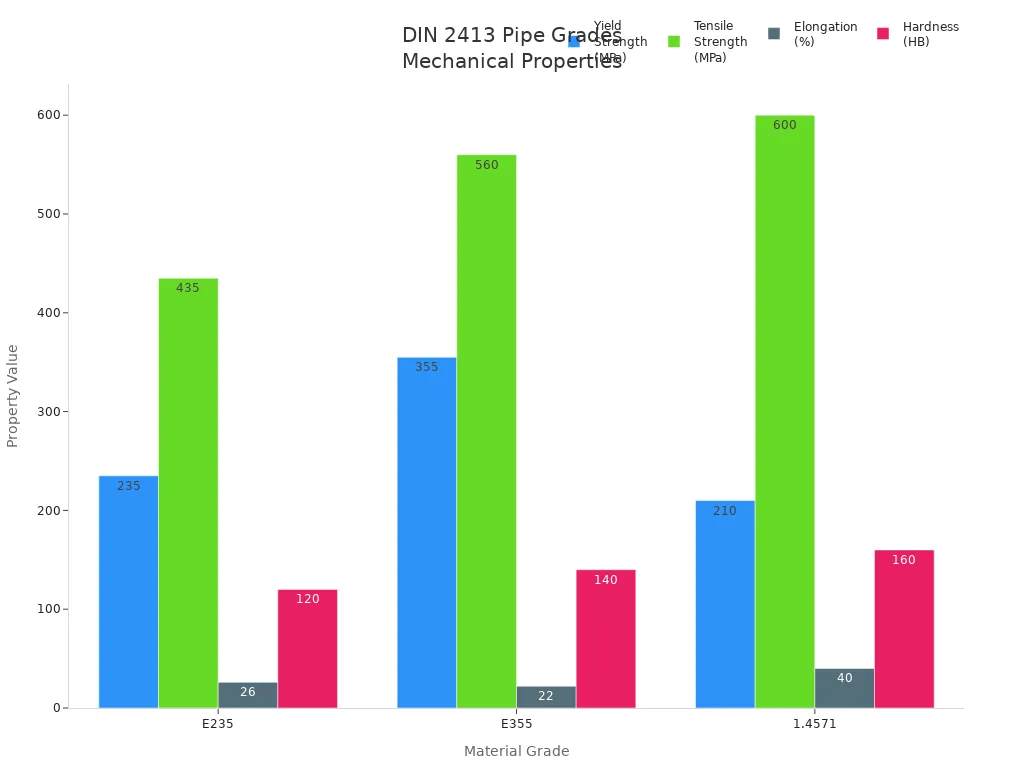

How well a hydraulic tube works depends on its material grade. DIN 2413 hydraulic seamless pipe seamless comes in different grades. Each grade has its own strength and hardness. The most common grades are E235, E355, and 1.4571. These grades have different yield strength, tensile strength, elongation, and hardness.

|

Grade |

Type |

Yield Strength (MPa) |

Tensile Strength (MPa) |

Elongation (%) |

Hardness (HB) |

Key Characteristics |

|---|---|---|---|---|---|---|

|

E235 |

Low carbon steel |

235 |

360-510 |

26 |

120 |

Good weldability and machinability; suitable for structural use |

|

E355 |

Higher carbon steel |

355 |

490-630 |

22 |

140 |

Higher strength for higher pressure applications |

|

1.4571 |

Austenitic stainless steel |

210 |

500-700 |

40 |

160 |

Excellent corrosion resistance; higher ductility |

E355 is the strongest and is good for hard jobs. 1.4571 stainless steel does not rust easily and bends well. E235 is easy to work with and has medium strength. These choices help seamless hydraulic tubes work for many different needs.

Fatigue and Corrosion Resistance

Hydraulic systems often face lots of pressure changes and tough conditions. Seamless hydraulic pipes are great at handling these changes. They do not crack or break easily, even after many uses. The seamless design means there are no weak welds, so the pipe stays strong.

Seamless hydraulic tubes also fight rust very well. Using good steel grades like 1.4571 stainless steel keeps the tubes safe from rust and chemicals. Special coatings, like black or oiled finishes, give even more protection. These things help seamless pipes last a long time, even with water, oil, or harsh fluids.

Note: Seamless hydraulic tubes are strong and resist rust, so they are trusted in important jobs like cars, planes, and big machines.

Hydraulic tubes must work well in hard places. Seamless hydraulic tubes do this by using strong materials and careful making. They also have good surface protection. This keeps hydraulic systems safe and working for a long time.

Hydraulic Seamless Pipe Seamless Standards

DIN 2413 Requirements

DIN 2413 has very strict rules for hydraulic tubes. These rules make sure each tube can handle high pressure and hard jobs. Engineers use DIN 2413 to check if tubes are strong enough for their work. The standard talks about wall thickness, material grades, and surface treatments.

Hydraulic tubes must meet certain pressure ratings at different temperatures. For example, a tube with a 4 mm outer diameter and 1.0 mm wall thickness can work at about 707 bar. Its burst pressure is 1755 bar. Pressure ratings change when it gets hot or cold. DIN 2413 gives reduction factors for these changes. Material grades like E355 and E235 help set the right pressure for each tube. Surface treatments like phosphate coating and NBK finish help stop rust and make tubes stronger.

|

Parameter www.torichsteel.com TORICH |

|---|

+ There are no comments

Add yours