Have you noticed how many industries today are searching for safer, lighter, and more durable thermal protection solutions? As machinery grows more advanced and working environments face higher temperatures, choosing the right heat-resistant material matters more than ever. HP3 heat shield materials are gaining strong attention because they offer stable performance, excellent thermal control, and reliable protection across many applications. Many factories and equipment manufacturers now view HP3 as a next-generation solution that supports both safety and efficiency.

Understanding the structure, performance, and benefits of HP3 heat shield materials can help buyers make smarter decisions. When used correctly, HP3 not only protects equipment but also boosts productivity and reduces maintenance downtime. In the following sections, we will explore what HP3 heat shields are, where they are used, and why more customers are choosing them. After that, we will highlight Weifen’s advantages as a trusted supplier offering stable quality, competitive pricing, and flexible customization for global clients.

What Is an HP3 Heat Shield

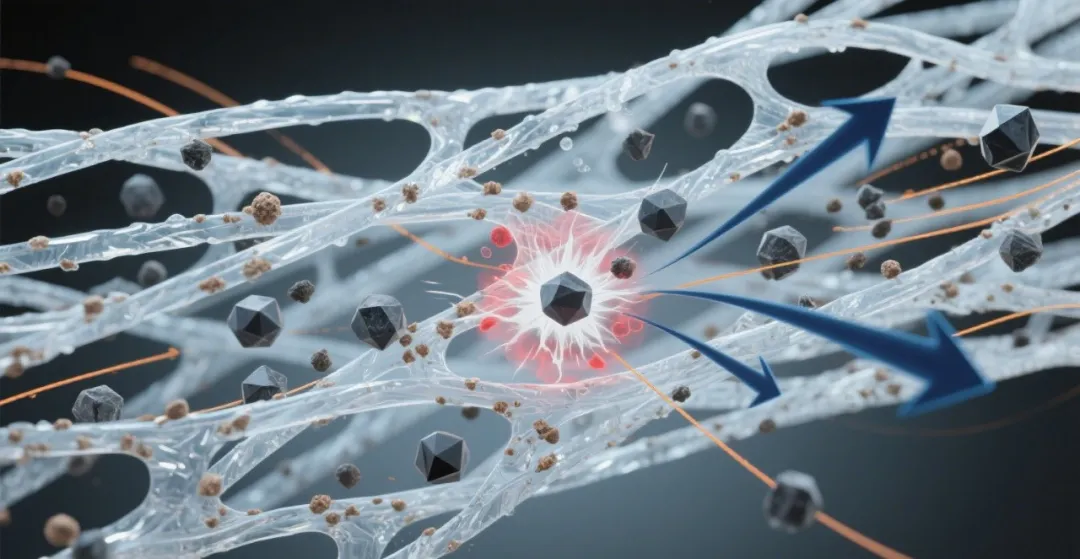

The HP3 heat shield is a high-performance thermal protection material designed for long-term exposure to high temperatures. Unlike traditional insulation sheets that rely solely on thickness or bulk density, HP3 combines engineered fibers, advanced coatings, and precise manufacturing processes to achieve superior resistance to heat, flame, and mechanical stress. Its structure can include fiberglass fabrics, ceramic fibers, metalized surfaces, or multilayer composites depending on the specific working environment.

The key advantage of HP3 is that it delivers reliable thermal barrier performance while remaining lightweight. This makes it an excellent choice for industries seeking energy-saving material solutions without compromising durability. The heat shield can effectively reduce radiant heat transfer, maintain stable temperatures within equipment, and prevent component fatigue caused by continuous thermal cycling. For buyers, this means stronger performance and lower long-term operating costs.

Transitioning from basic definitions to technical performance, it becomes clear why HP3 is widely applied in industries with heavy temperature demands. Many customers prefer HP3 because it stays stable even under sudden temperature spikes. It is also compatible with different surface treatments, allowing engineers to use it in complex or large-scale designs.

Main Features and Advantages of HP3 Heat Shield Materials

Before choosing a heat-resistant solution, buyers usually focus on temperature resistance, mechanical strength, installation flexibility, and environmental safety. HP3 performs well in all of these aspects, making it a strong candidate for demanding projects.

High Temperature Resistance

HP3 heat shield materials are engineered to withstand extreme heat without deformation or loss of strength. Depending on the grade, HP3 can handle continuous temperatures from 600°C to over 1200°C. This allows it to be used in harsh environments such as engine exhaust areas, industrial furnaces, hot processing lines, and high-heat mechanical systems.

Low Thermal Conductivity

A major benefit of HP3 is its excellent insulation effect. Its internal fiber structure slows down heat transfer and maintains stable surface temperatures. This helps protect sensitive components and reduces the risk of overheating.

Lightweight Design

Unlike traditional heat shields made of thick metal sheets, HP3 is significantly lighter. This reduces equipment load, improves energy efficiency, and makes installation easier—especially in automotive, electronics, and aerospace applications where weight control is critical.

Flexibility and Customization

HP3 heat shield materials are available in various thicknesses, shapes, and surface coatings. Engineers can choose reinforced edges, aluminum foil layers, protective coatings, or embossed textures depending on the environment. This allows the product to fit into complex mechanical structures.

Excellent Mechanical Strength

HP3 is manufactured to resist vibration, tearing, and abrasion. In equipment that experiences daily mechanical stress, this durability ensures long service life and reduces maintenance frequency.

Transitioning from features to applications, the benefits of HP3 become even clearer when matched with real-world environments. Whether in automotive or industrial production, HP3 materials offer stable results under constant heat exposure.

Where Are HP3 Heat Shields Used

HP3 heat shield materials are used in a wide range of industries because they meet the growing demand for thermal control and operational safety. Their flexibility allows them to be fitted into large machinery or compact mechanical components.

Automotive and Transportation

HP3 is often used around exhaust systems, turbochargers, battery enclosures, and engine compartments. As vehicles shift toward higher efficiency and electric-powered systems, precise temperature management becomes essential. HP3 helps stabilize temperatures and protect surrounding components.

Industrial Machinery

In factories and production lines, HP3 heat shields are installed on furnaces, dryers, kilns, hot pipelines, and thermal processing equipment. Many industrial clients choose HP3 because it reduces energy loss and maintains stable temperature conditions even during long operating cycles.

Electronics and Electrical Equipment

Electronic components such as inverters, power supply units, sensors, and circuit boards require thermal shielding to avoid heat damage. HP3 provides a lightweight, flame-resistant barrier without interfering with electrical performance.

Aerospace and High-Tech Applications

For aerospace manufacturing, HP3 materials offer high structural integrity, lightweight design, and resistance to extreme temperature changes. They are used in engine spaces, insulation panels, and thermal protective systems.

Before moving on to supplier recommendations, it’s important to note that HP3 heat shield selection often depends on the working environment. Factors such as heat source type, installation space, mechanical load, and safety requirements can influence the material grade. This is where a professional manufacturer can provide valuable technical support.

Why Choose Weifen as Your HP3 Heat Shield Supplier

Choosing the right supplier is just as important as choosing the right thermal insulation material. A reliable manufacturer ensures stable quality, consistent supply, and technical guidance across all project stages. Weifen stands out as a trusted partner known for material innovation, strict quality control, and customer-oriented service.

Below are the major strengths that make Weifen a preferred choice for global clients.

Strong Manufacturing Capabilities

Weifen operates with modern production lines that support large-volume output, stable processing quality, and fast delivery. Our factory uses advanced fiber forming and coating technologies to ensure each HP3 heat shield maintains uniform density, smooth surfaces, and long-term performance stability.

Strict Quality Control System

Every HP3 heat shield undergoes rigorous inspection, including thermal resistance tests, mechanical strength evaluation, and dimensional accuracy checks. Weifen follows international standards and provides product traceability from raw material to final shipment. This ensures every order meets the customer’s technical requirements.

Customized Engineering Solutions

Different industries and equipment have different thermal protection needs. Weifen offers complete customization services including size, thickness, coatings, reinforcement, and packaging. Our engineers work closely with clients to recommend the best HP3 grade and design for their application. This helps improve installation efficiency and reduce long-term maintenance costs.

Competitive Pricing for Global Buyers

One major advantage of working with Weifen is our cost-effective pricing strategy. Through efficient manufacturing and optimized raw-material sourcing, we provide high-performance HP3 heat shield materials at competitive prices. This makes Weifen an ideal supplier for distributors, OEM manufacturers, and project contractors.

Reliable After-Sales Service

Weifen’s technical team assists customers with installation guidance, performance evaluation, problem diagnosis, and long-term product support. Whether you need advice on product selection or after-delivery assistance, our service team responds quickly and professionally.

Transitioning toward the conclusion, customers seeking stable quality, flexible customization, and long-term supply reliability will find Weifen a dependable partner for HP3 heat shield solutions.

Conclusion: Your Trusted Partner for HP3 Heat Shield Materials

As industries move toward higher safety standards and more advanced equipment, HP3 heat shield materials are becoming essential for temperature management and equipment protection. Their high temperature resistance, lightweight design, and superior durability make them a strong choice for both traditional and modern applications. By partnering with a professional supplier like Weifen, customers gain access to stable quality, flexible customization options, and long-term technical support.

If you’re looking for a reliable provider of HP3 heat shield solutions for your industrial project, Weifen welcomes your inquiry. Our team is ready to deliver high-performance materials that meet your exact requirements and support your long-term success.

https://www.weifensh.com/hp3-heat-shield.html

Weifen

+ There are no comments

Add yours