In the construction industry, the choice of standard size for construction materials plays a crucial role in ensuring efficient building practices. The dimensions of materials used can impact various aspects of a construction project, including cost, structural integrity, and overall sustainability. This blog post aims to delve into the significance of selecting the right standard size of construction materials and its implications for construction professionals. By understanding the key factors and considerations involved, builders can make informed decisions that optimize their projects.

- The Importance of Standard Size Selection:

The selection of standard sizes for construction materials is vital for achieving cost-effective and efficient building practices. By adhering to standardized dimensions, builders can streamline the construction process, minimize waste, and enhance project timelines. Moreover, standardized sizes facilitate compatibility and interchangeability, allowing for easier integration of different components and materials. - Factors Influencing Standard Size Determination:

Several factors influence the determination of standard sizes for construction materials. These factors include structural requirements, manufacturing capabilities, transportation constraints, and industry regulations. Builders must consider the specific needs of their projects, such as load-bearing capacities, design specifications, and environmental considerations, to determine the most suitable standard sizes. - Common Standard Sizes for Construction Materials:

a. Lumber and Timber: Standard sizes for lumber and timber are typically based on nominal dimensions, such as 2x4, 4x6, etc. These dimensions are adjusted to account for the material's natural shrinkage during drying and processing.

b. Concrete Blocks: Concrete blocks are available in various standard sizes, including 8x8x16 inches, 12x8x16 inches, and 16x8x16 inches. These sizes are commonly used in residential and commercial construction projects.

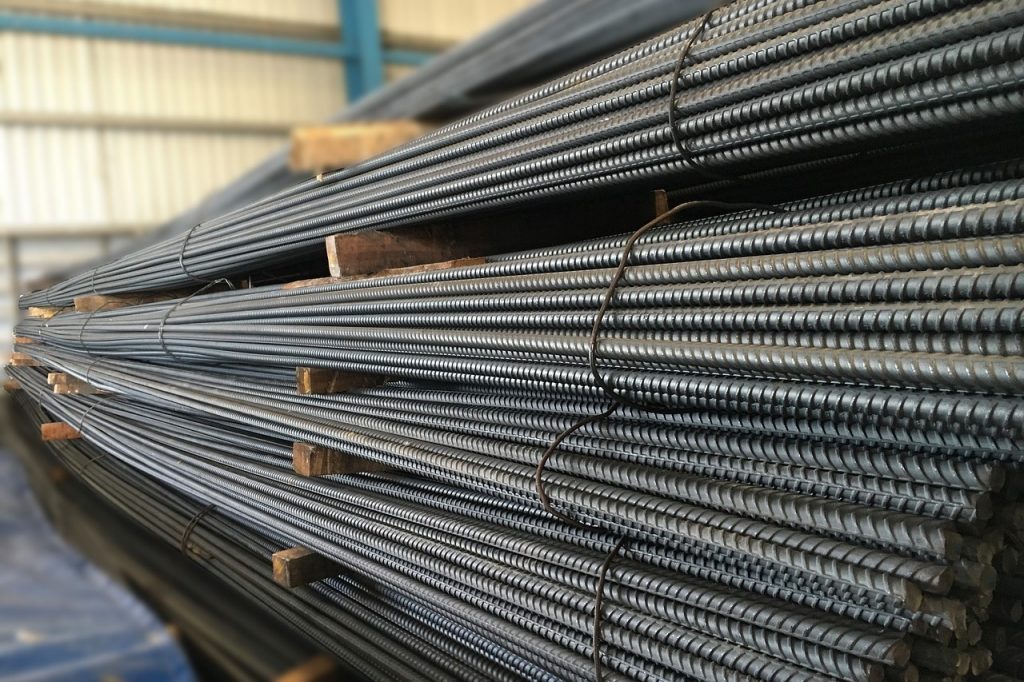

c. Steel Beams: Standard sizes for steel beams are determined based on load-bearing capacities and structural requirements. Common sizes include W6x9, W8x10, and W10x12, where the first number represents the depth and the second number represents the weight per foot.

d. Bricks: Bricks come in standard sizes, such as 4x8x2.25 inches or 3.625x8x2.25 inches. These sizes ensure uniformity in construction and facilitate efficient bricklaying techniques.

- Advantages of Standard Size Selection:

Choosing standard sizes for construction materials offers several advantages, including:

- Cost-effectiveness: Standard sizes are often readily available, reducing production costs and material waste.

- Interchangeability: Standard sizes enable easy replacement and integration of components, enhancing flexibility during construction.

- Compatibility: Standard sizes ensure compatibility between different materials and systems, promoting efficient construction practices.

- Industry Compliance: Adhering to standard sizes ensures compliance with industry regulations and building codes.

Conclusion:

Selecting the optimal standard size of construction materials is a critical decision that impacts the efficiency, cost-effectiveness, and sustainability of construction projects. By considering factors such as structural requirements, manufacturing capabilities, and industry regulations, builders can make informed choices that optimize their projects. Adhering to standardized dimensions facilitates compatibility, interchangeability, and cost savings, ultimately leading to successful construction outcomes.

+ There are no comments

Add yours