Concrete work looks simple from a distance: build a mold, place reinforcement, pour, and wait. In reality, the biggest risks—and the biggest schedule delays—often come from what’s holding everything in place while the concrete is still gaining strength. That’s why formwork and shoring should be treated as an engineered system, not a collection of temporary parts.

If you’re a contractor, project manager, or procurement team comparing suppliers, this article breaks down what “formwork & shoring” really covers, how to match systems to site conditions, and what quality signals matter before you place an order.

What “Formwork & Shoring” means on a jobsite

Formwork is the temporary (or semi-permanent) structure that shapes concrete. It’s responsible for the final geometry: walls, columns, slabs, beams, cores, and stair components. The formwork needs to be strong, stable, and accurate—because any deflection or leakage shows up directly in the finished concrete.

Shoring is the temporary support system that carries loads while the concrete cures. It holds up slabs, beams, and structural elements until they can safely carry their own weight and construction loads. Shoring also reduces risk during early stripping cycles and repeat pours on multi-level projects.

On most sites, formwork and shoring work together:

Formwork defines shape and finish

Shoring carries load and prevents collapse or excessive deflection

Where the right system makes the biggest difference

The “best” formwork and shoring choice depends on the project type, pour cycle, labor skill level, and safety plan. Here are common scenarios where selecting the right system is especially important:

1) Fast-cycle slab construction

When you’re pouring floor after floor, every hour matters. A well-planned shoring and reshoring approach helps maintain pace without risking early-age concrete failure.

2) High-rise and complex geometry

Tighter tolerances, more wind exposure, and heavier loads demand stable systems and consistent quality control—especially at connections and adjustment points.

3) Infrastructure and heavy pours

Large beams, thick slabs, and bridge components need predictable load paths, reliable bracing, and robust components that perform repeatedly across many pours.

4) Industrial and plant projects

These sites often involve tight layouts, heavy embedded items, and strict safety requirements. Modular, adjustable systems help reduce on-site improvisation.

A practical buyer’s checklist for Formwork & Shoring

Procurement often focuses on price first, but on active jobsites the real cost is downtime, rework, and safety risk. Use this checklist to compare systems and suppliers more realistically:

Load capacity and stability

Can the system handle the planned fresh concrete pressure and construction loads?

Are vertical and lateral stability measures clearly defined (bracing, ties, locking points)?

Adjustability and alignment

Are jacks, base plates, and adjustable heads robust and easy to fine-tune?

Is the system designed to maintain alignment through repeated use?

Speed of assembly

Does the system reduce the number of loose parts?

Are connections straightforward for the labor team you’ll actually have on site?

Durability and reuse

Can the components withstand repeated cycles without distortion?

Are wear points protected, and are replacement parts easy to source?

Site compatibility

Can it work with uneven ground, limited access, or congested areas?

Is it compatible with your existing scaffolding systems or site standards?

Common mistakes that cause delays (and how to avoid them)

Over-shoring without a plan

More material doesn’t automatically mean safer. Over-shoring can slow cycles, create congestion, and still fail if load paths aren’t correct. Good planning matters more than simply adding props.

Underestimating lateral forces

Vertical load is only part of the story. Wind, vibration, concrete placement dynamics, and uneven loading can introduce lateral movement. Bracing design and connection quality are key.

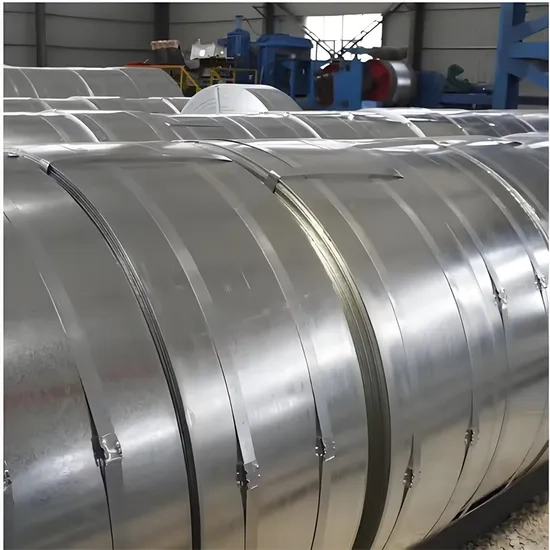

Inconsistent component quality

Temporary works are repeatedly assembled, disassembled, transported, and reassembled. If weld quality, steel consistency, galvanizing/coating, or locking mechanisms are inconsistent, performance becomes unpredictable.

Skipping a reshoring strategy

Removing support too early or without reshoring can lead to cracking, excessive deflection, or long-term structural issues. A good supplier can help you select systems that support your method statement and pour sequence.

Why supplier capability matters as much as the product

On paper, many systems look similar. In practice, reliable results come from consistent manufacturing and process control.

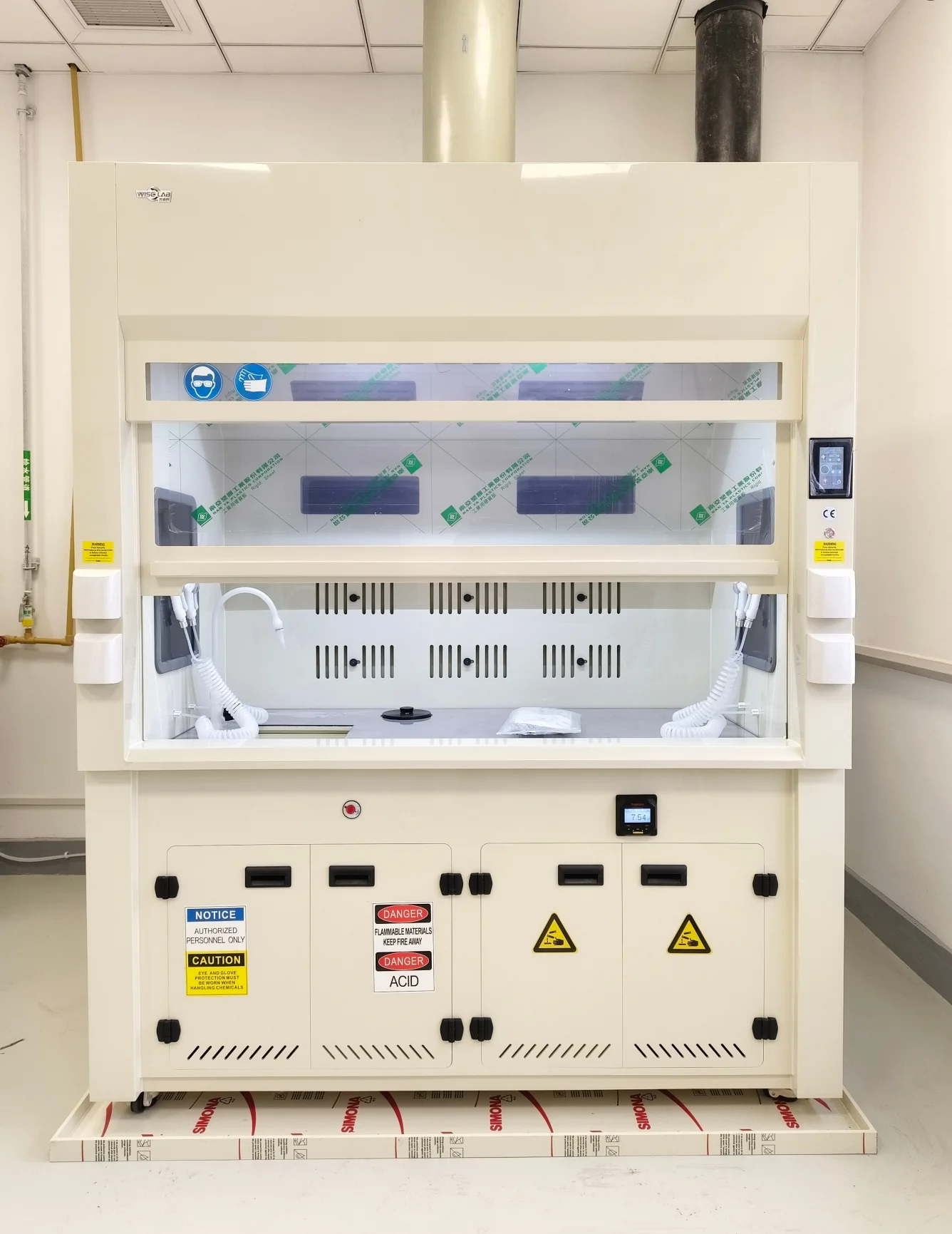

ZYD positions itself as a trusted supplier of scaffolding and formwork products—covering scaffolding systems, shoring, forming, fencing, and more—and emphasizes state-of-the-art manufacturing techniques and materials to meet varied project needs. That matters because “temporary” systems must still perform predictably under real loads and rough site handling.

If you’re comparing suppliers, look for:

Consistent material sourcing and traceability (where possible)

Stable welding and fabrication quality across batches

Fit-up accuracy at joints and locking points

Packaging and delivery discipline to reduce missing parts and site confusion

Communication support for system selection and project planning

How to match Formwork & Shoring to your project

If you want a simple decision framework, start with these questions:

What are you building? (slabs, beams, walls, cores, heavy infrastructure)

What is the cycle time target? (fast floors vs. slower heavy pours)

What’s the site condition? (uneven ground, tight access, high wind)

What labor skill level is available? (simple connections reduce errors)

What reuse rate do you need? (higher reuse needs stronger durability)

Then align the system type and component selection to the method statement—not the other way around.

Final takeaway

Formwork and shoring are not just “temporary.” They control concrete quality, protect workers, and directly influence schedule reliability. A practical approach—choosing systems based on load, cycle time, site conditions, and repeatable assembly—reduces risk and supports consistent pours.

For an overview of ZYD’s category offering, you can reference:

FORMWORK & SHORING

www.zydscaffold.com

Zhong Yue Da Hardware & Plastic Co., Ltd.

+ There are no comments

Add yours