https://www.shuangmane.com/Common-Faults-and-Solutions-of-Air-Preheater.html

The air preheater is an important device in many industrial processes. However, like any equipment, it may encounter various faults. This article will focus on discussing the common faults such as clogging and leakage, and their corresponding solutions.

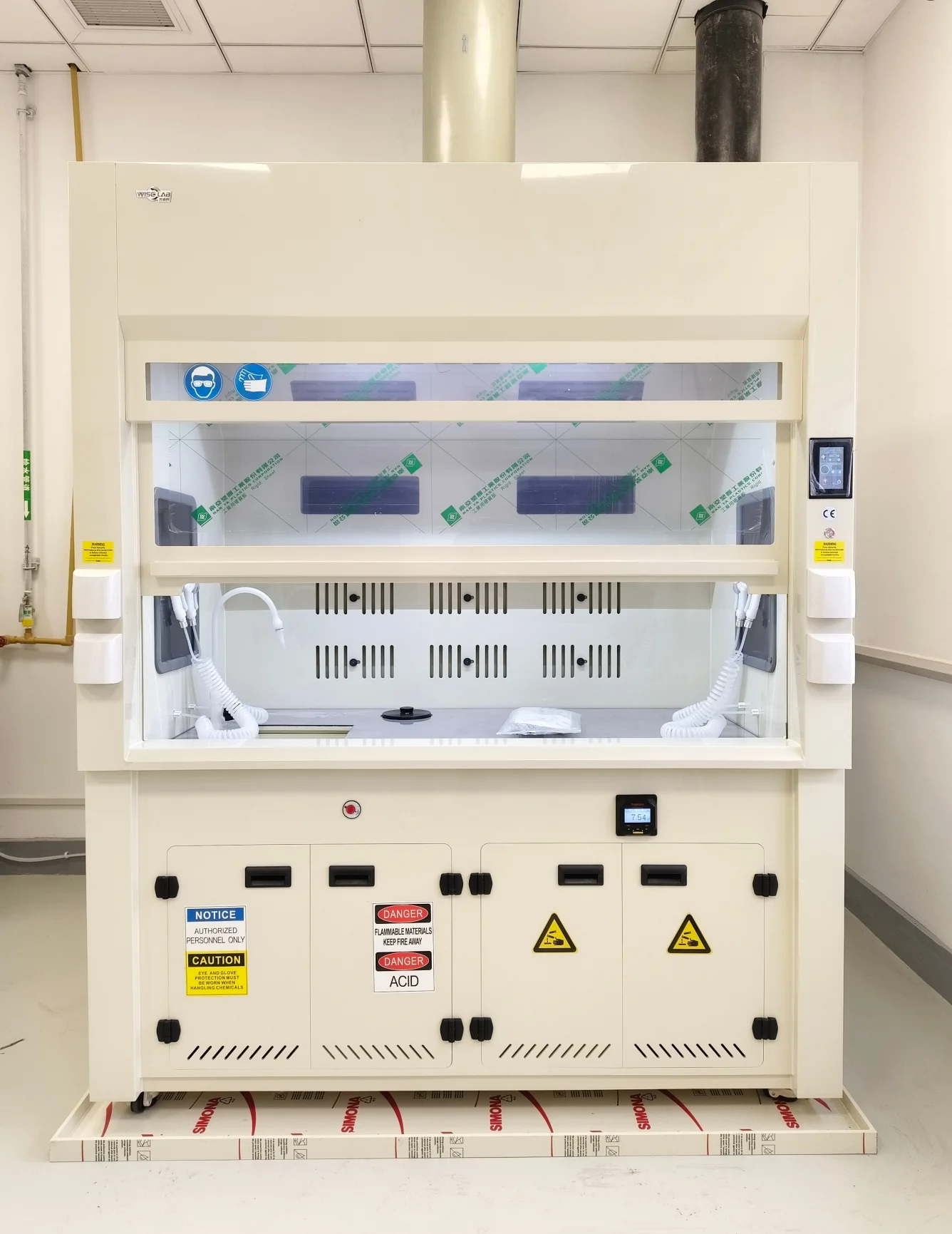

Air preheater

One of the common problems is clogging. Over time, dust, ash, and other particulate matter can accumulate in the air preheater, restricting the flow of air and reducing its efficiency. To address this issue, regular cleaning and maintenance are crucial. This can involve using compressed air or specialized cleaning tools to remove the accumulated debris. In some cases, installing filters upstream of the air preheater can help prevent excessive clogging.

Another fault is leakage. This can occur due to damaged seals, weld failures, or corrosion. When there is a leakage, it not only affects the performance of the air preheater but also may lead to energy losses. Inspecting the seals and welds regularly and replacing or repairing them as needed is an important measure. In case of corrosion, using corrosion-resistant materials or applying protective coatings can help prevent or mitigate the problem.

In addition to these, there may be issues with improper installation or alignment. This can result in uneven heating or airflow, affecting the overall performance. Ensuring correct installation and periodic checks for alignment are necessary. If any misalignment is detected, adjustments should be made promptly.

If the clogging is severe and cannot be resolved through regular cleaning, it might be necessary to consider more aggressive measures such as chemical cleaning or even replacing certain components. However, these options should be carefully evaluated to ensure they are cost-effective and do not cause additional damage.

For leakage caused by mechanical damage, immediate repairs should be carried out to avoid further deterioration. In some cases, it may be necessary to shut down the system temporarily to carry out the necessary repairs effectively.

To prevent these faults from occurring frequently, a preventive maintenance program is essential. This includes regular inspections, cleaning, and checks of all components. Training the operating and maintenance personnel on proper handling and maintenance procedures can also significantly reduce the occurrence of faults.

Moreover, monitoring the performance of the air preheater regularly can help detect any potential problems at an early stage. By analyzing data such as temperature differentials, pressure drops, and airflows, early signs of clogging or leakage can be identified and addressed promptly.

In conclusion, understanding and addressing the common faults of the air preheater, such as clogging and leakage, are critical for its smooth operation and optimal performance. By implementing proper maintenance strategies, including regular cleaning, inspections, and repairs, and by having a proactive approach to fault detection and prevention, the reliability and efficiency of the air preheater can be greatly improved. This not only benefits the specific industrial process but also has a positive impact on overall energy consumption and operational costs.

https://www.shuangmane.com/Common-Faults-and-Solutions-of-Air-Preheater.html

Jiangsu Shuangma New Energy Equipment Co., Ltd.

+ There are no comments

Add yours