In industrial operations, the performance and reliability of heavy-duty machinery are often dictated by the quality of their critical components. Among these, medium and large bearings play a pivotal role in ensuring smooth operation, minimizing downtime, and sustaining high productivity across demanding applications. From fertilizer production to industrial fermentation processes, bearings form the foundation that allows machinery to handle heavy loads, extreme speeds, and continuous operation.

This article explores how medium and large bearings enhance industrial performance and highlights how Sawei Equipment Technology, a specialist in complete process equipment, integrates these components into heavy-duty machinery for optimal efficiency.

The Role of Bearings in Heavy-Duty Machinery

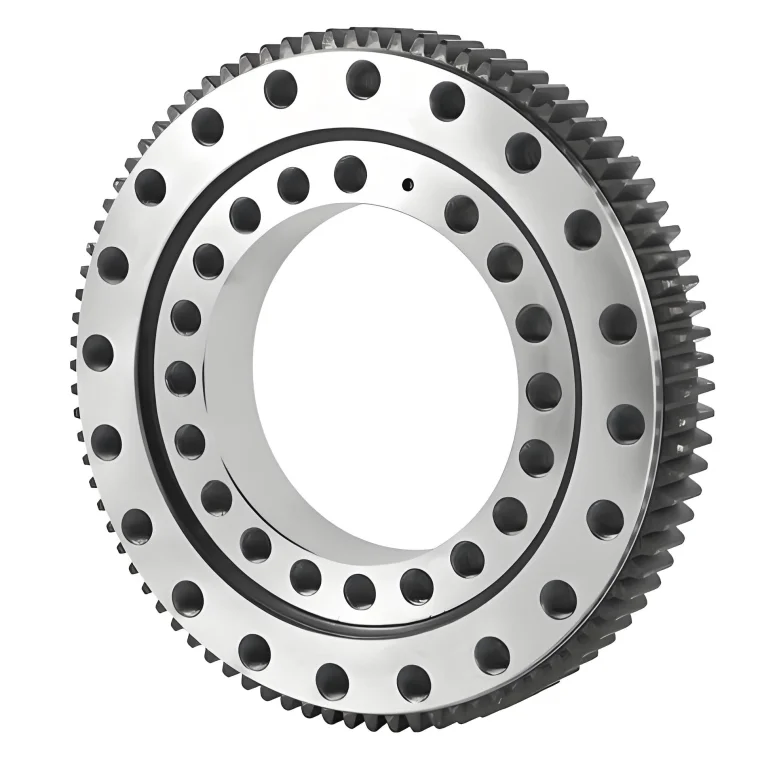

Bearings are mechanical elements designed to support rotating or moving parts, reduce friction, and maintain alignment under load. In heavy-duty industrial equipment, medium and large bearings are indispensable because they:

-

Support high radial and axial loads

-

Reduce friction and wear in rotating shafts and rollers

-

Maintain precise alignment for consistent operation

-

Extend the service life of machinery under continuous use

For industries handling dense materials, high pressures, or continuous production cycles, reliable bearings are essential for maintaining operational efficiency and equipment longevity.

Key Benefits of Medium and Large Bearings

1. Load Handling Capability

Medium and large bearings are specifically designed to manage heavy loads that standard bearings cannot support. They can sustain:

-

High radial loads from rotating drums, rollers, and shafts

-

Axial thrust in vertical or inclined equipment

-

Shock and vibration from intermittent heavy-duty processes

This ensures machinery can operate at maximum capacity without risk of premature failure.

2. Friction Reduction and Energy Efficiency

By minimizing friction between moving components, bearings help reduce:

-

Energy consumption in motors and drive systems

-

Heat generation that could damage surrounding components

-

Wear and maintenance frequency

Efficient bearings directly contribute to lower operational costs and smoother plant performance.

3. Vibration and Noise Control

Precision bearings absorb and distribute loads evenly, helping:

-

Reduce vibrations in high-speed equipment

-

Maintain stability in long rotating shafts

-

Minimize noise levels for safer working environments

Stable and quiet machinery also improves product quality and reduces wear on connected components.

4. Longevity and Reliability

High-quality medium and large bearings, when properly installed and maintained, can operate for years under demanding conditions. Extended service life reduces downtime, enhances safety, and ensures predictable maintenance scheduling.

Applications in Heavy-Duty Industrial Equipment

Medium and large bearings are critical in a wide range of industrial machinery, including:

-

Rotors and drums in fertilizer manufacturing lines

-

Centrifuges and reactors in chemical processing

-

Conveyors, mixers, and crushers handling dense or abrasive materials

-

Industrial fermenters and gas treatment equipment

In industries such as fertilizer production and bio-fermentation, where continuous operation is crucial, bearings ensure machinery can withstand high loads while maintaining stable performance.

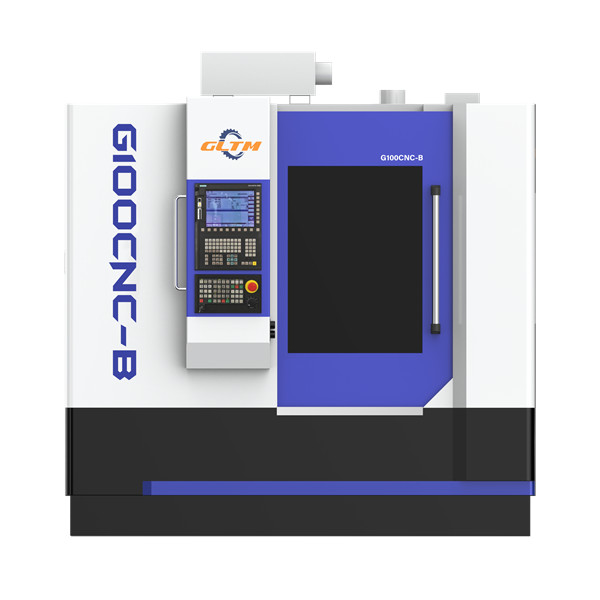

How Sawei Equipment Technology Integrates Bearings into Industrial Machinery

Sawei Equipment Technology specializes in developing complete process equipment solutions for heavy-duty industrial sectors. Their core expertise spans:

-

Agrochemical Industry: Phosphate chemical, sulfur chemical, ammonium phosphate, and compound potassium sulfate fertilizer projects

-

Bio-Fermentation and Industrial Environmental Protection: Handling carbon-containing waste gases, waste oils, and other recovery processes

For all these applications, Sawei integrates medium and large bearings into machinery to ensure:

-

Smooth operation of mixers, reactors, and drums

-

High durability under continuous heavy-load processing

-

Reliable alignment of rotating shafts and critical components

By combining precision engineering with specialized knowledge of industrial processes, Sawei enhances equipment performance and production efficiency.

Choosing the Right Bearing for Your Machinery

Selecting suitable medium or large bearings involves several considerations:

-

Load Capacity: Ensure the bearing can handle maximum radial and axial loads.

-

Speed Rating: Bearings must accommodate operational speed without overheating.

-

Material and Coating: Corrosion-resistant or heat-resistant materials may be required depending on the industrial environment.

-

Lubrication and Maintenance: Proper lubrication and maintenance schedules extend bearing life.

-

Alignment and Installation: Correct installation prevents premature wear and enhances operational stability.

Professional guidance from equipment specialists like Sawei ensures bearings are selected and integrated effectively for optimal machinery performance.

Maintenance and Longevity Tips

To maximize the life of medium and large bearings in heavy-duty equipment:

-

Implement regular lubrication schedules

-

Monitor temperature and vibration levels during operation

-

Inspect bearings periodically for wear or damage

-

Replace bearings proactively before catastrophic failure

Consistent maintenance minimizes unplanned downtime and maintains high production efficiency.

Conclusion

Medium and large bearings are essential components that enable heavy-duty machinery to operate reliably under demanding industrial conditions. By supporting high loads, reducing friction, controlling vibration, and extending service life, bearings directly influence industrial performance, safety, and operational efficiency.

With its expertise in complete process equipment for agrochemical and bio-fermentation industries, Sawei Equipment Technology integrates medium and large bearings into machinery to enhance durability, performance, and reliability. For industries where continuous heavy-duty operation is critical, investing in high-quality bearings and proper machinery design is a cornerstone of long-term success.

www.swasps.com

JIANGSU SAWEI EQUIPMENT TECHNOLOGY CO.,LTD

+ There are no comments

Add yours