Orbital welding machines have become essential equipment in industries requiring high-precision and contamination-free joints, including pharmaceuticals, semiconductors, food processing, chemical engineering, and clean energy systems. Unlike manual welding, orbital welding delivers fully automated and repeatable welds, minimizing operator error and ensuring consistent performance. However, achieving top-tier weld quality still depends on several critical factors that influence the welding outcome.

This article explores the key factors that directly affect weld quality when using orbital welding machines. Understanding these elements helps manufacturers, engineers, and technicians maintain stable operation, reduce defects, and extend the service life of welded pipelines and components.

1. Precision of Welding Parameters

One of the core advantages of orbital welding is its ability to control welding parameters with high precision. However, even small deviations can severely impact weld quality.

1.1 Welding Current

Welding current determines penetration depth and heat input.

-

Too high: Over-penetration, burn-through, excessive heat-affected zone (HAZ).

-

Too low: Lack of fusion, weak weld seam.

High-end orbital welding power sources—such as inverter-based digital systems—allow real-time adjustments during welding, ensuring heat control remains accurate even when material conditions change.

1.2 Welding Speed

Travel speed affects bead formation, fusion uniformity, and overall weld appearance.

-

Too fast: Undercut, poor fusion.

-

Too slow: Excessive heat input, distortion, oxidation.

Modern orbital systems synchronize rotation speed with current output to deliver uniform welds throughout the entire circumference.

1.3 Shielding Gas Flow & Purity

For stainless steel and other corrosion-resistant alloys, argon or mixed-gas quality directly affects oxidation levels.

-

Impure gas → discoloration, porosity, loss of corrosion resistance.

-

Incorrect flow → turbulent shielding or back purging issues.

High-performance orbital welding machines often include gas monitoring and automatic shutdown to prevent weld contamination.

2. Quality and Stability of the Orbital Welding Power Source

The power source is the heart of an orbital welding system. Its stability determines whether the weld remains consistent under changing thermal loads.

2.1 Inverter Stability

Advanced inverter technology ensures:

-

smooth waveform output,

-

stable arc ignition,

-

precise control of each welding phase.

Machines with poor inverter stability produce inconsistent arcs, leading to defects such as spattering, uneven penetration, or unstable bead shapes.

2.2 Digital Control and Programmability

Modern orbital welding power sources include:

-

parameter libraries,

-

automatic welding program generation,

-

offline programming,

-

U-disk or remote software upgrades.

These features reduce human error and allow operators to store optimized parameters for different pipe diameters and wall thicknesses, ensuring repeatable quality.

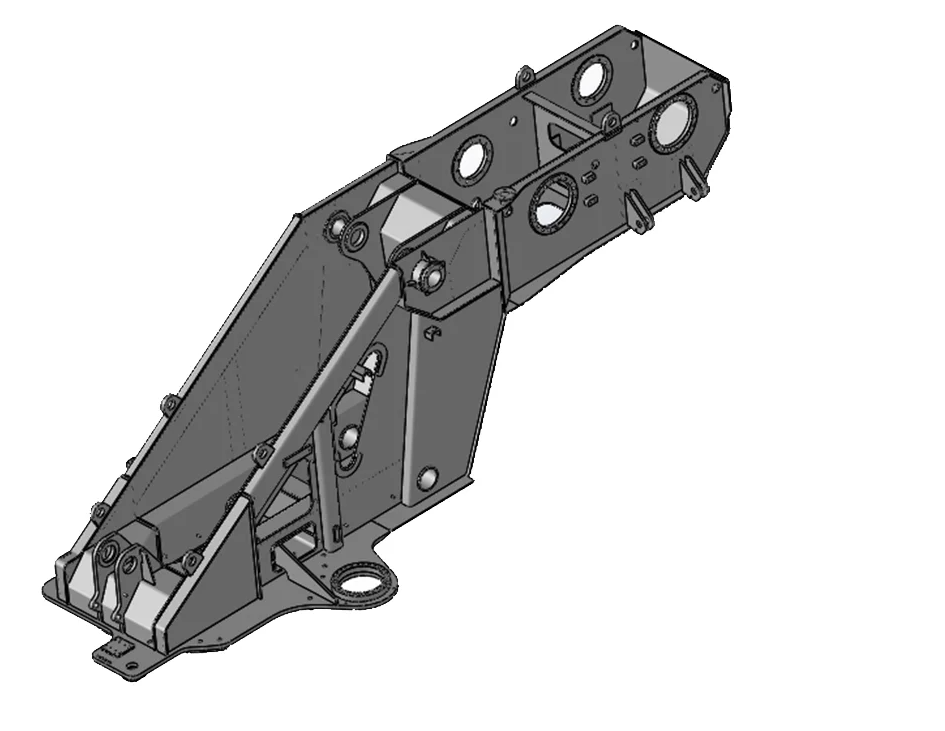

3. Selection and Compatibility of Welding Heads

Even the best power source cannot deliver high-quality welds if paired with the wrong welding head.

3.1 Correct Welding Head Type

Closed-chamber welding heads (e.g., BH series) are ideal for thin-walled stainless-steel tubes used in industries requiring ultra-clean welds. They provide:

-

complete shielding gas coverage,

-

stable arc environment,

-

uniform weld penetration.

Open-type heads are more suitable for large-diameter pipes or applications requiring filler wire.

3.2 Mechanical Stability

Factors that influence mechanical stability include:

-

bearing quality,

-

rotation accuracy,

-

gear alignment,

-

cooling channel integrity.

Any mechanical vibration or rotation lag will affect bead uniformity, resulting in weld defects such as mismatch, waviness, or incomplete fusion.

3.3 Cooling Efficiency

Welding heads must maintain stable temperatures to avoid overheating:

-

insufficient cooling → thermal deformation, electrode wear, gas turbulence.

-

efficient cooling → consistent arc, longer equipment lifespan.

Water-cooling and gas-cooling systems should be checked regularly to ensure stable performance.

4. Material Characteristics and Pipe Preparation

The weld quality also depends on how well the material is prepared before welding.

4.1 Pipe Surface Cleanliness

Contaminants such as oil, dust, or moisture can cause:

-

porosity,

-

inclusions,

-

poor fusion.

Pipes must be cleaned with approved solvents and kept dry prior to welding.

4.2 Pipe Alignment and Clamping

Even slight misalignment affects weld penetration. High-precision clamping tools ensure:

+ There are no comments

Add yours