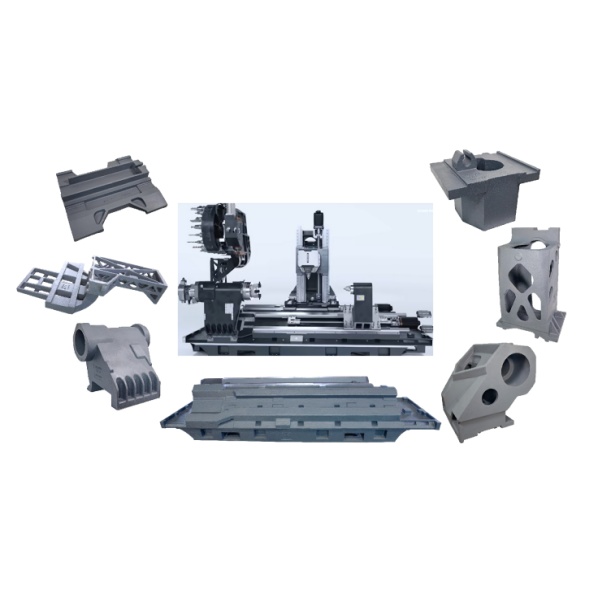

Choosing the right vertical milling center is a critical decision for manufacturers aiming to achieve precision, efficiency, and versatility in their operations. Vertical milling centers are essential in industries like automotive, aerospace, mold making, and precision casting. Selecting a machine that aligns with your production requirements can enhance product quality, reduce operational costs, and improve overall workflow. Companies like Casteks Metal Science (Jiangsu) Co., Ltd.) exemplify how integrating advanced vertical milling centers with modern casting processes can deliver superior results.

Founded in 2013, Casteks has accumulated extensive industry experience by combining the expertise of professionals with global management knowledge. In 2019, Casteks officially took over Suzhou Casting Factory and its subsidiary STK Technology (Jiangsu) Co., Ltd., creating a powerful synergy between advanced casting and precision machining. Their holistic approach includes a marketing center, an engineer innovation center, and a supply chain management center, enabling them to provide full-process services from product design to production and delivery.

Understanding Vertical Milling Centers

A vertical milling center is a CNC (Computer Numerical Control) machine where the spindle axis is vertically oriented. The workpiece moves along multiple axes while the cutting tool performs precise operations. Unlike traditional manual milling, vertical milling centers offer automation, high repeatability, and the ability to handle complex geometries, making them suitable for industries with stringent precision requirements.

Before investing in a vertical milling center, it’s crucial to understand the key specifications that will impact performance, productivity, and adaptability in your manufacturing environment.

Key Specifications to Consider

1. Spindle Type and Power

-

The spindle is the core of a vertical milling center. It dictates the type of materials you can machine and the range of operations the machine can perform. Consider the following:

-

Spindle Power: Higher spindle power allows cutting harder materials and performing heavier operations without compromising precision.

-

Spindle Speed: Variable speed control provides flexibility for different materials and cutting techniques.

-

Spindle Taper Type: Compatibility with standard tooling ensures ease of use and tool availability.

-

At Casteks, vertical milling centers are chosen with spindle capabilities that complement the hardness and complexity of cast components produced by STK Technology, ensuring efficient and precise machining.

2. Table Size and Travel

The dimensions of the machine table and the travel limits along the X, Y, and Z axes determine the maximum size of workpieces and the flexibility of operations:

-

Table Size: Larger tables accommodate bigger components or multiple smaller components simultaneously, increasing throughput.

-

Travel Distance: Extended travel allows machining of complex parts with long profiles or multi-step operations.

-

Casteks’ production of automotive and aerospace components benefits from vertical milling centers with adequate table size and travel to handle both standard and intricate cast parts.

3. Accuracy and Repeatability

Precision is critical, especially for industries with tight tolerances such as aerospace or mold making. Look for:

-

Positional Accuracy: The machine’s ability to position the tool at the exact coordinates.

-

Repeatability: The ability to perform identical operations consistently across multiple parts.

-

Casteks ensures that every cast component refined through vertical milling meets strict quality standards, combining the accuracy of CNC machining with advanced casting processes.

4. Automation Features

Automation can drastically improve production efficiency:

-

Tool Changers: Reduce downtime by automatically switching between cutting tools.

-

Fixture Automation: Enhances repeatability and reduces manual intervention.

-

CNC Control Software: Integration with CAD/CAM software allows precise programming and simulation.

-

Casteks’ engineer innovation center leverages CNC automation to streamline the machining of cast components, optimizing workflow and reducing human error.

5. Rigidity and Machine Construction

A milling center’s structural rigidity affects machining stability and surface finish quality. Machines with robust frames resist vibrations and maintain precision during heavy-duty operations. For cast components with intricate details, this is crucial. Casteks selects machines with high rigidity to ensure consistent quality for both simple and complex parts.

6. Compatibility with Materials

Different industries use various materials, including aluminum, steel, titanium, and specialty alloys. The milling center must handle these materials efficiently without compromising precision or surface finish. Vertical milling centers at Casteks are capable of machining a wide range of metals, complementing the company’s expertise in advanced casting processes.

7. Integration with Existing Workflow

Finally, consider how the milling center will integrate into your current workflow. Features to assess include:

-

Compatibility with CAD/CAM software

-

Ease of maintenance and spare part availability

-

Adaptability to future production needs

At Casteks, vertical milling centers are integrated with casting operations, supply chain management, and product design, creating a seamless production ecosystem that enhances efficiency and ensures timely delivery.

Conclusion

Selecting the right vertical milling center involves more than just evaluating specifications; it requires understanding your production goals, material requirements, and workflow integration. Key factors such as spindle power, table size, accuracy, automation, rigidity, and material compatibility all play a role in ensuring that the machine meets your manufacturing needs.

By combining advanced vertical milling centers with precision casting, Casteks Metal Science (Jiangsu) Co., Ltd.) demonstrates how modern manufacturing technologies can work in tandem to produce high-quality components for automotive, aerospace, and mold making industries. Their holistic approach—from design and development to production and delivery—sets a benchmark for efficient, precise, and reliable manufacturing solutions.

Investing in the right vertical milling center is a strategic decision that enhances productivity, precision, and flexibility, ensuring your operations remain competitive in a rapidly evolving industrial landscape.

www.casteks.com

Casteks Metal science (iangsu)Co., Ltd.

+ There are no comments

Add yours