In gas and water pipeline systems, even the smallest connection plays a critical role in determining long-term safety and efficiency. A single weak joint can compromise an entire network, leading to leaks, maintenance issues, and costly downtime. This is where electrofusion technology — and specifically, the Electrofusion Reducer — stands out as one of the most reliable innovations in modern piping systems.

As infrastructure demands higher performance and durability, understanding how this technology ensures a leak-free connection becomes vital. In this article, we’ll explore how electrofusion reducers work, their advantages, and how Ningbo Lianda Plastics Pipe Fitting Co., Ltd. has advanced this technology through precision engineering and certified manufacturing.

1. What Is an Electrofusion Reducer?

An electrofusion reducer is a PE pipe fitting designed to connect pipes of different diameters while maintaining the strength and reliability of the system. It allows seamless transitions between varying pipe sizes, ensuring consistent flow rates in gas and water pipelines.

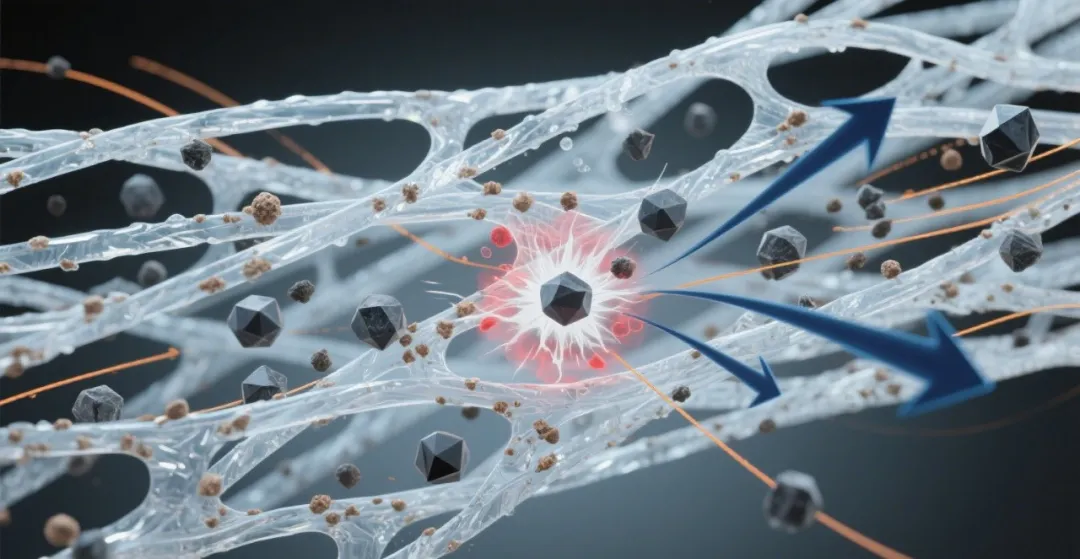

The reducer’s innovation lies in its built-in electrical heating coils. When a controlled electric current passes through these coils, they generate localized heat that melts the inner surface of the fitting and the outer surface of the connected pipes. Once cooled, the materials fuse into a single, continuous structure — forming a homogeneous joint that is as strong and durable as the pipe itself.

This process eliminates the use of adhesives, mechanical joints, or external sealing components. The result is a permanent, leak-free connection ideal for both buried and pressurized pipeline systems.

2. How Electrofusion Technology Ensures Leak-Free Performance

Traditional pipeline joining methods often rely on mechanical compression or manual welding. Both approaches can create weak points due to uneven heating, alignment issues, or environmental factors during installation. Electrofusion, by contrast, provides automated precision and consistency.

Key aspects that make the connection leak-free include:

-

Controlled Heating: Electrofusion machines deliver a specific current and duration based on the fitting’s barcode, ensuring optimal melting without over- or under-heating.

-

Uniform Pressure: The heating coils are evenly distributed within the fitting, providing consistent bonding pressure across the entire circumference.

-

Material Homogeneity: The fusion process merges the molecules of the pipe and fitting, eliminating potential gaps or stress points.

-

No Mechanical Weaknesses: Since there are no bolts or gaskets involved, there are no components that can loosen or degrade over time.

These attributes make electrofusion reducers particularly effective for buried PE gas pipeline systems, where long-term reliability and minimal maintenance are paramount.

3. Why Electrofusion Reducers Are Vital in Gas and Water Pipelines

Gas and water pipelines are expected to perform flawlessly under high pressure, temperature changes, and soil movement. Any compromise in the joint can lead to severe consequences — from gas leaks posing safety hazards to water system inefficiencies that waste valuable resources.

The Electrofusion Reducer solves these challenges by offering:

-

Seamless Transitions Between Diameters: It maintains consistent pressure and flow without turbulence or cavitation.

-

Resistance to Environmental Stress: PE materials and fusion joints resist corrosion, chemical attack, and mechanical strain.

-

Long-Term Durability: The joint remains stable over decades of underground use without degradation.

-

Compatibility: Designed to integrate with a wide range of PE pipes and fittings in modern infrastructure.

For both urban water networks and natural gas systems, the electrofusion reducer ensures safe, stable operation under demanding conditions.

4. The Science Behind Electrofusion Welding

At its core, electrofusion technology relies on the precise balance of electrical current, temperature, and time. Here’s a simplified view of the process:

-

Preparation: Pipe ends are cleaned and scraped to remove oxidation and contaminants.

-

Insertion: Pipes are inserted into the electrofusion reducer until they meet the central stops.

-

Fusion: The control unit supplies current through the fitting’s coils, melting the contact surfaces.

-

Cooling: As the materials cool, they solidify into one continuous, strong joint.

The success of this process depends on accurate manufacturing of both the fitting and the heating element. This is where Lianda’s production expertise ensures performance consistency across all fittings.

5. Lianda’s Commitment to Precision and Quality

Ningbo Lianda Plastics Pipe Fitting Co., Ltd. is a modern, international manufacturer specializing in PE pipe fittings and ball valves for gas and water applications. The company holds ISO9001, ISO14001, and ISO45001 certifications, ensuring strict control over quality, environment, and occupational safety.

With advanced production technology, multiple national patents, and years of industry experience, Lianda has developed a complete product line that adheres to national standards for buried PE gas pipeline systems.

Each electrofusion reducer is:

-

Manufactured with High-Precision Equipment — ensuring consistent dimensions and accurate coil placement.

-

Tested for Fusion Reliability — every batch undergoes pressure and sealing tests before shipment.

-

Built for Durability — resistant to pressure fluctuations, chemical corrosion, and soil movement.

-

Compliant with Global Standards — compatible with international gas and water pipeline systems.

Lianda’s emphasis on precision at every production step ensures that its products deliver the leak-free performance required for critical infrastructure.

6. Electrofusion Reducers vs. Other Connection Methods

| Connection Method | Sealing Principle | Installation Complexity | Leak Resistance | Maintenance Demand |

|---|---|---|---|---|

| Electrofusion Reducer | Molecular fusion (no gaps) | Moderate | Excellent | Very low |

| Butt Fusion Joint | Heated joint interface | High (requires alignment) | Good | Moderate |

| Mechanical Coupling | Rubber gasket compression | Low | Fair | Requires periodic inspection |

As this comparison shows, electrofusion reducers provide a balanced combination of ease of installation, long-term reliability, and exceptional sealing performance. This makes them a preferred choice in modern pipeline construction, especially for projects emphasizing safety and sustainability.

7. Practical Applications in Real-World Projects

Lianda’s electrofusion reducers are widely used across various sectors:

-

Municipal Gas Distribution: Providing secure transitions between main and branch pipelines.

-

Water Supply Networks: Maintaining flow efficiency and preventing leakage over long distances.

-

Industrial Systems: Handling chemicals and high-pressure fluids in factory or process pipelines.

-

Rural Infrastructure: Supporting agricultural irrigation and local water delivery systems.

Their adaptability to different operating conditions makes them indispensable in both large-scale urban projects and small community networks.

8. The Future of Leak-Free Piping Solutions

As industries move toward more sustainable and intelligent infrastructure, demand for reliable, maintenance-free pipeline connections continues to rise. Electrofusion technology is already being integrated with smart monitoring systems that can record fusion parameters for quality tracking and digital documentation.

For manufacturers like Ningbo Lianda Plastics Pipe Fitting Co., Ltd., innovation goes beyond product design — it extends to automation, digital inspection, and eco-friendly production processes. The company’s focus on research and development ensures continuous improvement in performance, reliability, and sustainability.

www.enovarps.com

Ningbo Lianda Plastics Pipe Fitting Co., Ltd.

+ There are no comments

Add yours