In today’s industrial landscape, safety, accuracy, and real-time monitoring are no longer optional — they’re essential. Nowhere is this more critical than in hydrogen sulfide (H₂S) detection. A toxic gas with potentially deadly effects, H₂S requires fast, stable, and interference-resistant sensing technology. Hydrogen sulfide sensors are evolving rapidly, driven by advancements in sensor design, material science, and digital integration. This guide explores the latest trends in H₂S sensor technology and how modern solutions — such as those developed by top-tier manufacturers — are transforming industrial safety and efficiency.

1. From Basic Detection to Intelligent Sensing

In the early days, hydrogen sulfide sensors were designed solely for basic detection — trigger an alert when gas exceeded a threshold. Today, sensors are part of smart, interconnected systems. Modern H₂S sensors collect continuous data, integrate with control platforms, and even enable predictive maintenance by alerting operators of irregular trends before failure occurs.

These advancements are made possible by built-in microprocessors and enhanced algorithms. As a result, users no longer get just a “yes or no” reading; they get a stream of actionable insights.

2. Shift Toward Electrochemical Sensor Technology

Among all sensing technologies for H₂S, electrochemical sensors have become the gold standard due to their high sensitivity, low power consumption, and fast response time. Modern electrochemical H₂S sensors now feature longer lifespans, greater temperature tolerance, and improved stability in high-humidity or interference-prone environments.

Shenzhen ProSense Technology Co., Ltd. has been at the forefront of this innovation. Since 2015, the company has focused on improving gas sensing platforms, and its H₂S sensor products reflect their core strength in electrochemical sensing, designed for maximum stability and minimum drift.

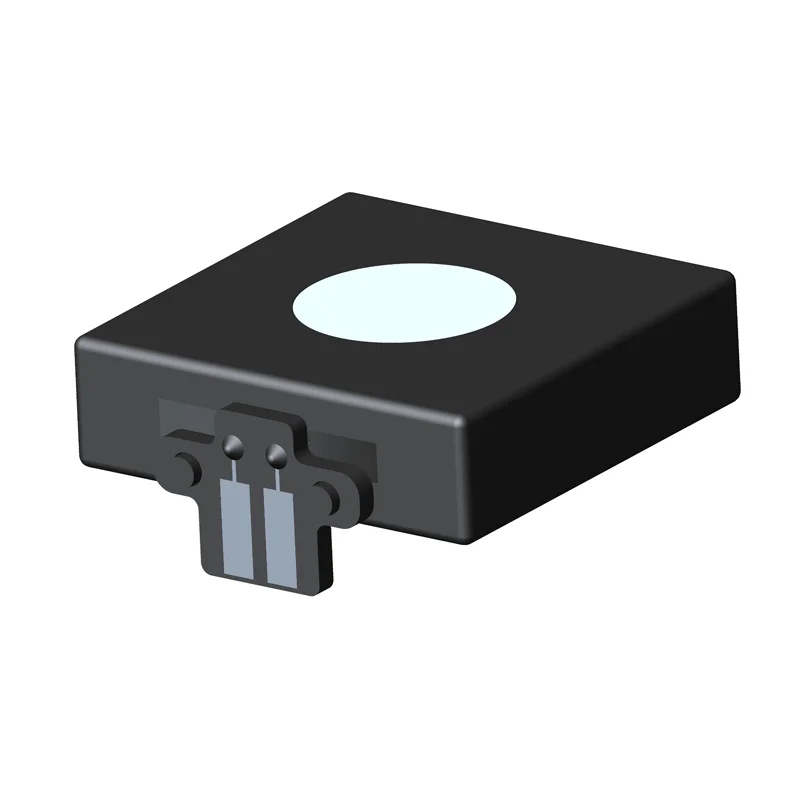

3. Miniaturization for Flexibility and Integration

Industrial design is shifting toward compact, low-profile sensors that can be embedded in tight or mobile spaces — from confined mining tunnels to IoT-enabled ventilation ducts. This miniaturization trend doesn’t mean compromising performance. Today’s compact hydrogen sulfide sensors deliver the same accuracy and reliability as their bulkier predecessors.

For integrators and system engineers, this enables flexibility in design and the ability to embed sensors into smart systems, handheld detectors, or mobile environmental monitors.

4. Enhanced Interference Resistance for Harsh Environments

One of the key pain points in H₂S detection is cross-sensitivity — when the sensor responds to gases other than hydrogen sulfide, like SO₂ or CO. The latest H₂S sensor technologies are designed to tackle this through selective membranes and advanced filtering algorithms that minimize false alarms.

At ProSense, this design principle is fundamental. Their sensors are engineered to maintain performance even in the presence of complex gas mixtures — a frequent challenge in wastewater treatment plants, petrochemical facilities, and tunnels.

5. Integration into Industrial IoT (IIoT) Platforms

With the rise of smart factories, digital connectivity is transforming how H₂S sensors are used. Modern sensors are now often equipped with RS485, MODBUS, or even wireless communication modules like LoRaWAN or NB-IoT. These allow seamless integration with centralized dashboards, giving safety managers a real-time view of gas levels across a facility.

This trend also supports predictive maintenance — a major cost-saving feature. By analyzing sensor data over time, operators can predict when recalibration or replacement will be needed, reducing downtime and improving long-term reliability.

6. Automated Calibration and Quality Assurance

Manual calibration and aging used to be a significant bottleneck. Now, advanced production facilities use automated calibration systems to ensure consistent quality and faster lead times. These systems not only reduce human error but also allow for tighter tolerances in sensor performance.

ProSense’s production lines incorporate automated aging and calibration technologies, ensuring each hydrogen sulfide sensor delivers accurate, ready-to-use performance before it reaches the customer. This commitment to quality is a key factor behind their delivery of over 10 million gas sensors worldwide.

7. Regulatory Compliance and Global Safety Standards

Industries such as oil & gas, mining, and waste management operate under strict environmental and worker safety regulations. Therefore, H₂S sensors must comply with global standards like ATEX, IECEx, CE, or UL certifications depending on the application region.

Modern hydrogen sulfide sensors are now designed with these requirements in mind, ensuring not just performance but also compliance — especially for systems exported globally or installed in regulated sectors.

8. Sustainability and Sensor Longevity

Sustainability isn't just about energy anymore — it's also about product lifespan. New H₂S sensors are being engineered for longer operational lives, with extended calibration intervals and low environmental impact materials. This reduces waste, operating costs, and ensures sensors are a long-term asset rather than a recurring expense.

With in-house R&D, patented designs, and a commitment to technological improvement, companies like ProSense lead this shift toward sustainable sensing without compromising precision.

Conclusion

As industries evolve, so too must the technologies that protect them. Hydrogen sulfide sensors are no longer just simple detectors — they are smart, stable, and integral parts of industrial safety systems. From electrochemical innovation to IIoT integration, today’s sensor technology is reshaping how we detect toxic gases. For any organization seeking reliable H₂S monitoring in complex or high-risk environments, embracing modern sensor technology isn’t just smart — it’s essential.

Investing in the right hydrogen sulfide sensor means investing in long-term safety, efficiency, and peace of mind.

www.cnprosense.com

Shenzhen ProSense Technology Co., Ltd.

+ There are no comments

Add yours