In the realm of tools and equipment, power tools play a pivotal role in various industries. However, it is crucial to understand the fundamental differences between stationary and portable power tools to make informed decisions when it comes to selecting the right tool for a specific task. This article aims to delve into the disparities between these two types of power tools, shedding light on their unique features, applications, and advantages.

- Definition and Overview:

Stationary Power Tools:

Stationary power tools are large, heavy-duty machines designed to remain fixed in a specific location, typically in workshops or manufacturing facilities. These tools are powered by electricity or other energy sources and are known for their stability, precision, and ability to handle complex tasks.

Portable Power Tools:

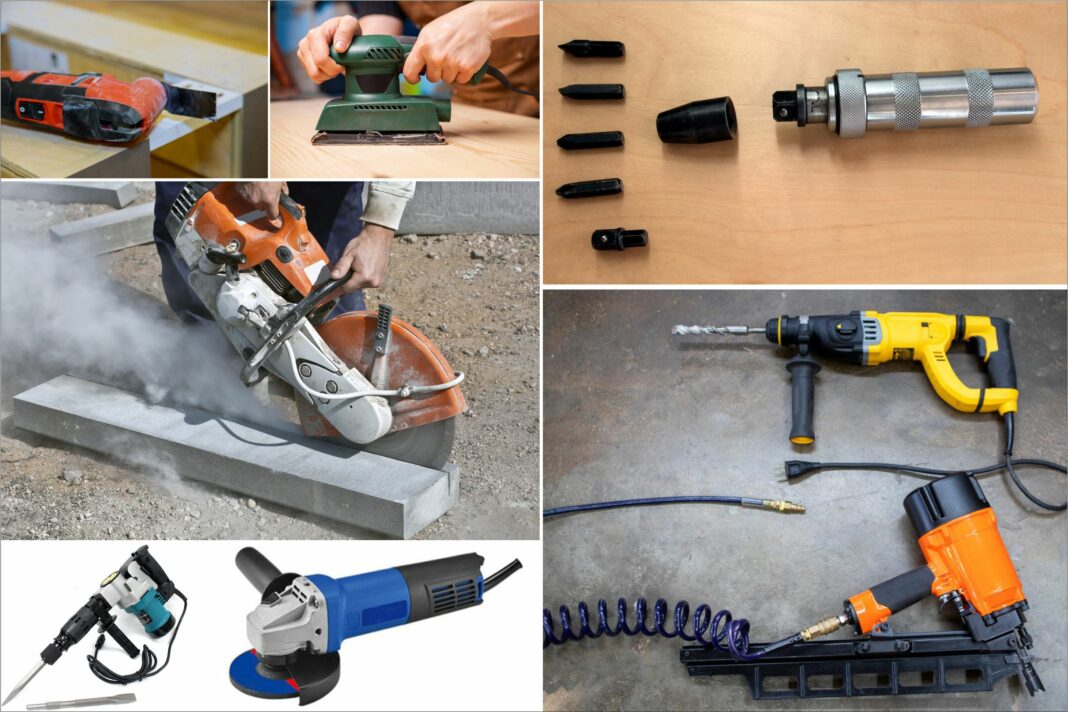

Portable power tools, as the name suggests, are handheld devices that can be easily carried and used at various job sites. They are compact, lightweight, and powered by electricity, batteries, or fuel. Portable tools offer flexibility, maneuverability, and convenience, making them suitable for tasks that require mobility.

- Applications and Versatility:

Stationary Power Tools:

Due to their robust construction and stability, stationary power tools excel in tasks that demand high precision and power. They are commonly used in woodworking, metalworking, and construction industries. Examples include table saws, drill presses, and jointers. These tools are ideal for creating intricate designs, shaping materials, and achieving consistent results.

Portable Power Tools:

Portable power tools are versatile and find applications in a wide range of industries, including construction, automotive, and DIY projects. Tools like cordless drills, angle grinders, and circular saws offer convenience and mobility, enabling professionals and enthusiasts to work efficiently in various locations. Their compact size allows access to tight spaces and facilitates quick repairs or modifications.

- Performance and Power:

Stationary Power Tools:

Stationary tools are designed for heavy-duty tasks and are equipped with powerful motors, enabling them to handle demanding applications. They provide consistent power output, ensuring precise cuts, smooth finishes, and efficient material removal. Additionally, stationary tools often incorporate advanced features like adjustable fences, digital displays, and dust collection systems, enhancing accuracy and safety.

Portable Power Tools:

While portable tools may not match the power of their stationary counterparts, they still offer impressive performance for their size. Technological advancements have led to the development of cordless tools with high-capacity batteries, providing ample power for most tasks. These tools prioritize maneuverability and ease of use, allowing professionals to work efficiently in diverse environments.

- Safety Considerations:

Stationary Power Tools:

As stationary power tools are larger and more powerful, they require proper setup, maintenance, and safety precautions. Operators must be well-trained to operate these tools safely, as they can cause severe injuries if mishandled. Safety features like blade guards, emergency stop buttons, and kickback prevention mechanisms are crucial to minimize risks.

Portable Power Tools:

While portable tools are generally safer to use due to their smaller size, operators must still adhere to safety guidelines. Proper handling, wearing appropriate personal protective equipment, and ensuring a stable work surface are essential. Additionally, cordless tools eliminate the risk of tripping over cords, enhancing overall safety.

Conclusion:

Understanding the distinctions between stationary and portable power tools is vital for professionals and enthusiasts alike. Stationary tools excel in precision and power, making them suitable for complex tasks, while portable tools offer versatility and mobility. By considering the specific requirements of a project, individuals can make informed decisions and select the most appropriate tool for the job at hand, ensuring efficiency, safety, and optimal results.

+ There are no comments

Add yours