In the realm of automotive engineering, fuel pumps play a crucial role in ensuring the efficient delivery of fuel to the engine. The pressure exerted by a fuel pump is a critical factor that directly impacts engine performance and overall fuel efficiency. In this blog post, we will delve into the intricate mechanics behind fuel pump pressure, exploring its significance, factors affecting it, and its implications for engine operation.

- The Significance of Fuel Pump Pressure:

Fuel pump pressure refers to the force exerted by the pump to push fuel from the tank to the engine. It is a vital parameter that determines the rate at which fuel is supplied, ensuring optimal combustion and power generation. Insufficient pressure can lead to fuel starvation, resulting in engine misfires, reduced power output, and increased emissions. On the other hand, excessive pressure can strain the fuel system, leading to leaks, component failures, and potential safety hazards. - Factors Affecting Fuel Pump Pressure:

Several factors influence the pressure exerted by a fuel pump, including:

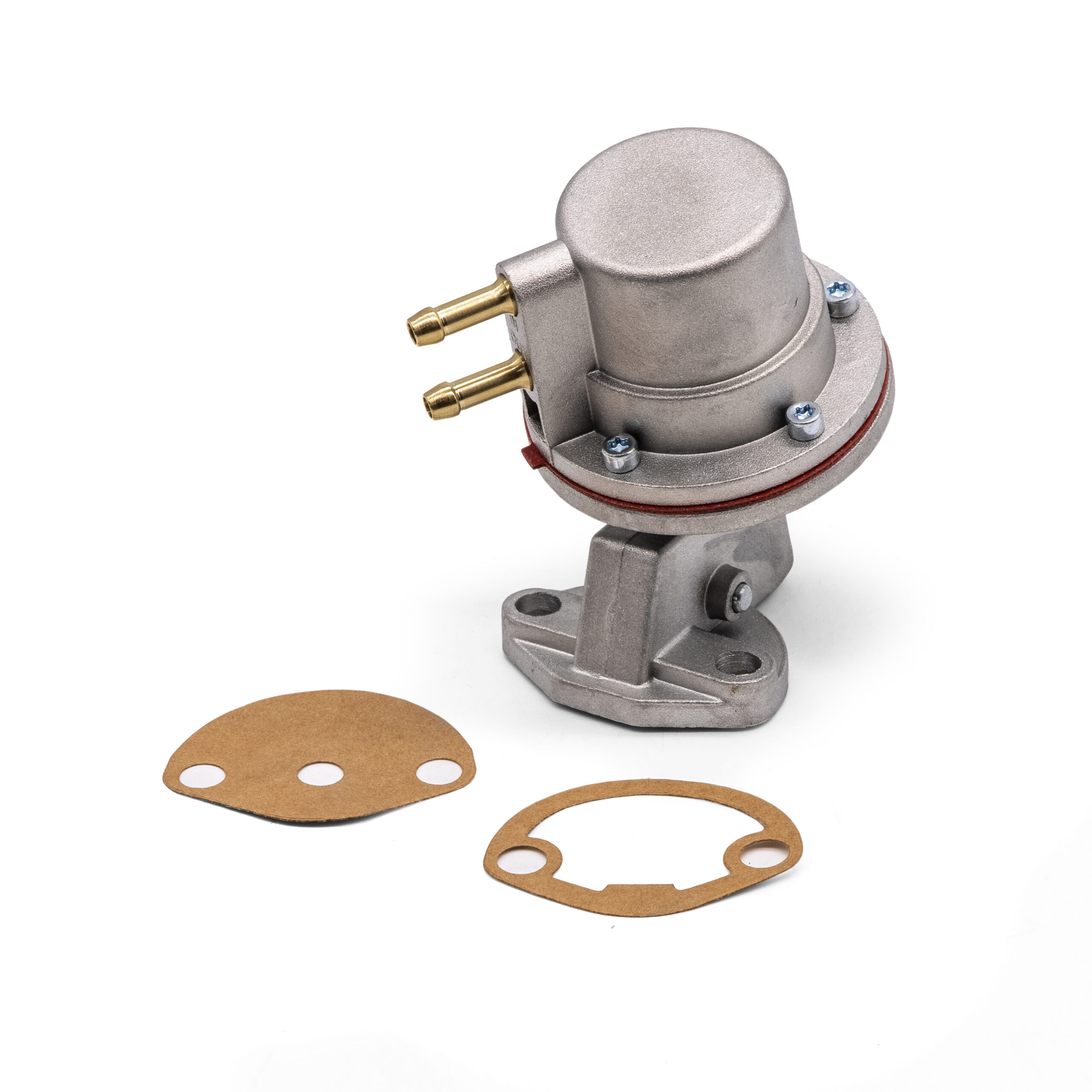

a. Fuel Pump Type: Different fuel pump designs, such as mechanical, electric, and direct injection pumps, have varying pressure capabilities. Understanding the specific pump type and its pressure range is crucial for optimal engine performance.

b. Fuel System Design: The overall design and configuration of the fuel system, including the fuel lines, filters, and regulators, can impact the pressure delivered by the pump. Proper sizing and maintenance of these components are essential to maintain consistent pressure levels.

c. Engine Requirements: Engine specifications, such as displacement, compression ratio, and fuel injection system, determine the fuel demand and, consequently, the required pump pressure. Matching the pump's output to the engine's needs is vital for efficient operation.

- Implications for Engine Operation:

The pressure exerted by the fuel pump has several implications for engine performance:

a. Fuel Atomization: Optimal pressure ensures proper atomization of fuel, breaking it into fine droplets for efficient combustion. Inadequate pressure can result in poor atomization, leading to incomplete combustion, reduced power, and increased emissions.

b. Fuel Injection Timing: Fuel pump pressure influences the timing and duration of fuel injection. Precise control over pressure allows for accurate fuel delivery, optimizing combustion efficiency and power output.

c. Fuel Economy: Maintaining the correct pressure ensures that the engine receives the required amount of fuel, preventing wastage and promoting fuel economy. A well-calibrated fuel pump pressure contributes to improved mileage and reduced operating costs.

Conclusion:

Understanding the pressure dynamics of fuel pumps is crucial for automotive enthusiasts, engineers, and technicians alike. By comprehending the significance of fuel pump pressure, the factors influencing it, and its implications for engine operation, we can optimize fuel delivery, enhance performance, and promote fuel efficiency. Whether it's a mechanical, electric, or direct injection pump, maintaining the right pressure ensures the heart of the engine beats at its best.

+ There are no comments

Add yours