In the world of heavy-duty industrial equipment, ball mills are essential machines used for grinding materials into fine powder. Whether in mining, fertilizer production, or chemical processing, their performance directly affects production efficiency and product quality. One of the most critical components of a ball mill's smooth operation is the bearing bush—a seemingly small part with a massive responsibility.

As an innovative developer of complete process equipment, Sawei Equipment Technology specializes in offering tailored solutions to sectors like phosphorus and sulfur-based fertilizers, compound fertilizers such as SOP (sulfate of potash), and industrial bio-fermentation. For these industries, understanding and maintaining core components like the ball mill bearing bush is vital for continuous, efficient operation.

This article explores what a ball mill bearing bush is, its main functions, and how it supports a wide range of industrial applications.

What Is a Ball Mill Bearing Bush?

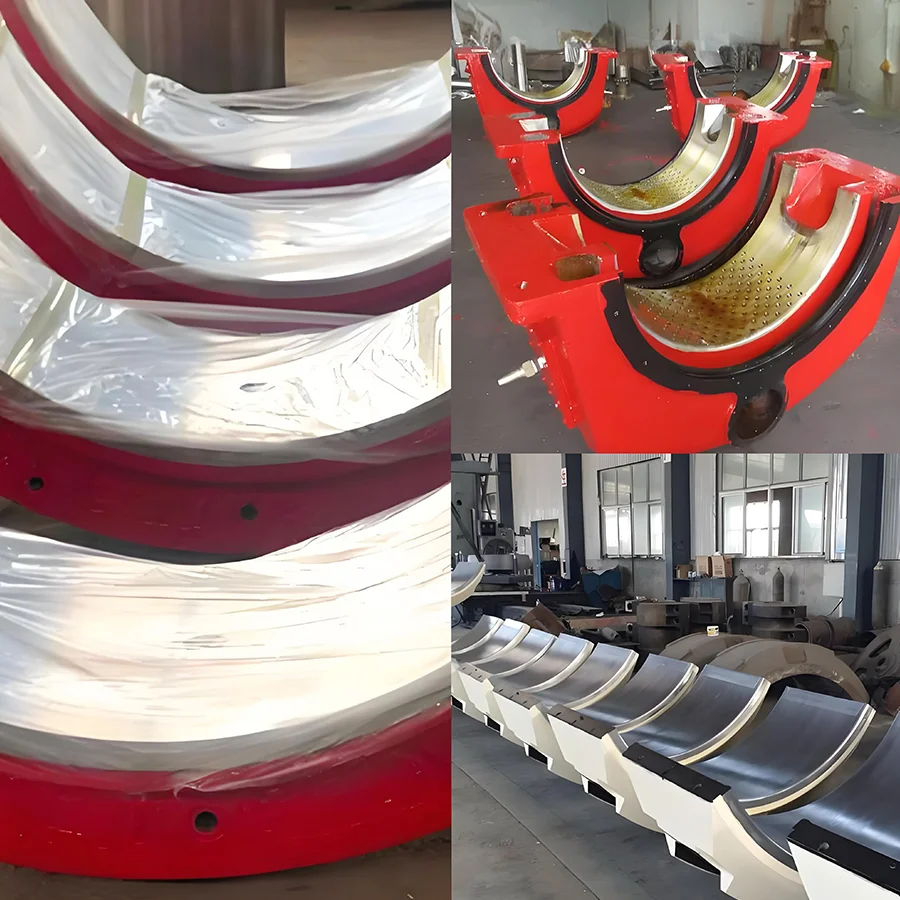

A bearing bush, also known as a bearing sleeve or plain bearing, is a type of mechanical component designed to support the rotating shaft inside a ball mill. It serves as the contact surface between the mill’s rotating shaft and its fixed housing. Unlike rolling bearings that use balls or rollers, bearing bushes rely on a sliding motion between surfaces, usually enhanced with lubrication.

In ball mills, the bearing bush is typically made of high-strength materials like bronze, Babbitt alloy, or customized wear-resistant composites—designed to handle heavy radial loads, high temperatures, and continuous rotation over long production cycles.

Key Functions of the Ball Mill Bearing Bush

-

Load Support and Rotation Control

The bearing bush holds the ball mill’s rotating shaft in position, allowing it to spin consistently under immense loads. -

Minimized Friction

With proper lubrication, it reduces the friction between the rotating parts and the housing, improving energy efficiency. -

Vibration Absorption

Unlike some rigid bearing types, bushes offer slight flexibility, helping to absorb vibrations and reduce noise levels during operation. -

Wear Resistance

Engineered to withstand high stress, bearing bushes are designed for durability under extreme grinding environments. -

Thermal Stability

Ball mills often generate significant heat during operation. Bearing bushes are constructed to resist heat-related deformation, protecting both the shaft and mill structure.

Industrial Applications Across Key Sectors

1. Phosphate and Sulfur-Based Fertilizer Production

In the phosphorus and sulfur chemical industries, such as phosphate fertilizer or ammonium phosphate manufacturing, ball mills are used to grind raw materials like phosphate rock and sulfur compounds. Here, bearing bushes must withstand corrosive conditions and abrasive media—an area where Sawei Equipment Technology’s engineered solutions deliver superior reliability.

2. Compound Fertilizer (SOP) Plants

In sulfate of potash (SOP) and other NPK compound fertilizer systems, smooth ball mill operation is crucial for uniform particle size distribution. Bearing bushes play a silent but powerful role in ensuring that grinding processes remain stable and low-maintenance.

3. Industrial Bio-Fermentation Facilities

In the waste gas and waste oil recycling sectors, where biological fermentation systems process volatile organic compounds (VOCs), ball mills may be used to treat biomass or catalyst media. Here, bearing bushes help guarantee efficient operation in round-the-clock production settings—fitting perfectly into Sawei’s broader commitment to industrial environmental protection.

4. Cement, Metallurgy, and Mining

While outside Sawei’s core sectors, ball mill bearing bushes are also widely used in cement kilns, metallurgical refineries, and ore processing facilities—demonstrating the part’s cross-industry importance.

Why Choose High-Quality Bearing Bushes?

Poor-quality bearing bushes can lead to:

-

Unexpected machine downtime

-

Increased maintenance costs

-

Shaft misalignment or damage

-

Inefficient energy use

That’s why choosing the right equipment supplier—like Sawei Equipment Technology, with deep industry know-how and a systems-level engineering approach—is crucial. The company doesn’t just deliver individual parts; it offers fully integrated process solutions that align every component, from raw material handling to grinding, mixing, and beyond.

Conclusion: A Small Component with a Big Job

Though often overlooked, the ball mill bearing bush is a key factor in the efficient and reliable operation of grinding systems across many industries. From supporting massive loads to maintaining precise shaft alignment, it’s a component that demands attention, engineering precision, and proper care.

For companies operating in fertilizer production, bio-fermentation recovery, or chemical process industries, Sawei Equipment Technology brings the right blend of technical expertise, material science, and process integration to ensure your ball mill systems run at peak performance.

www.swasps.com

Jiangsu Sawei Equipment Technology Co., Ltd.

+ There are no comments

Add yours