In modern electrical and grounding applications, achieving both high conductivity and mechanical strength is often a trade-off. However, Sunlightweld copper clad steel stranded conductor delivers both — seamlessly combining copper's excellent electrical conductivity with the tensile strength of steel. Designed for demanding environments and long-term reliability, this conductor provides an optimized balance of performance, durability, and cost-efficiency.

As a professional supplier, manufacturer, and factory of earthing materials, grounding products, and lightning protection systems, Sunlightweld leverages its strong Chinese supply chain advantages to deliver exceptional products at factory-direct prices. This not only ensures top quality but also enables global customers to achieve 30–50% cost savings compared to other international brands — significantly increasing profit margins and competitiveness.

What Is the Copper Clad Steel Stranded Conductor?

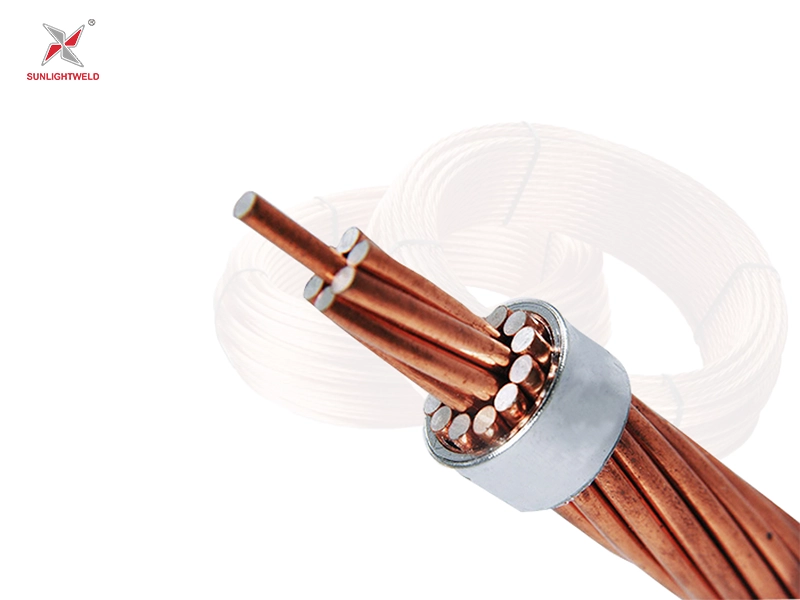

A copper clad steel stranded conductor is a composite electrical conductor made by bonding a uniform layer of high-conductivity copper onto a high-strength steel core. The result is a hybrid material that exhibits the best attributes of both metals: copper's superior electrical conductivity and steel's mechanical resilience. The conductor typically consists of several stranded wires, each with a steel core and copper coating. Through advanced metallurgical bonding, the copper and steel form a permanent union that ensures consistent performance throughout the product's lifetime.

Unlike pure copper conductors, which can be heavy and expensive, or pure steel wires, which may suffer from high resistance, copper clad steel stranded conductors deliver an optimal balance between conductivity, strength, corrosion resistance, and cost-efficiency. This makes them particularly well-suited for earthing systems, lightning protection, telecommunications grounding, and transmission applications, where reliability and longevity are non-negotiable.

Sunlightweld Copper Clad Steel Stranded Conductor Features

The Sunlightweld copper clad steel stranded conductor is meticulously engineered to deliver unmatched performance, long lifespan, and cost-effectiveness. It reflects a commitment to quality, customization, and value — making it a preferred choice for engineers and project owners worldwide.

1. Customizable Copper Layer Thickness (0.254–0.8 mm)

The international standard for copper cladding is 0.254 mm, but Sunlightweld offers an extended customizable range from 0.254 to 0.8 mm, giving customers the flexibility to select the best configuration for their project. Whether optimizing conductivity for sensitive electrical systems or enhancing corrosion resistance for harsh outdoor environments, this adaptability ensures a perfect match between design and performance. By precisely controlling copper thickness and bonding quality, Sunlightweld ensures a consistent copper-to-steel ratio throughout the conductor, resulting in stable resistance values and long-term durability.

2. IEC & UL Certified for Global Standards

Each Sunlightweld copper clad steel stranded conductor is certified under IEC and UL standards, ensuring it meets stringent global safety and performance benchmarks. Customers can deploy it confidently across regions without worrying about certification or compliance issues.

3. Factory-Direct Manufacturing for Consistent Quality and Cost Savings

Sunlightweld owns its production facilities, which allows full control over every stage — from raw material sourcing to final inspection. This not only ensures consistent product quality but also provides factory-direct prices. Customers benefit from 30–50% cost savings compared to competitors that rely on trading intermediaries.

4. Superior Electrical Conductivity

The advanced copper bonding process ensures a continuous, uniform copper layer that delivers excellent electrical conductivity, comparable to pure copper. This makes the Sunlightweld copper clad steel stranded conductor an ideal choice for grounding and lightning protection systems, where low resistance and stable current flow are essential.

5. Enhanced Mechanical Strength and Durability

The steel core provides high tensile strength, allowing the conductor to withstand extreme tension, bending, and environmental stress during installation and operation. This mechanical resilience ensures the conductor performs reliably even in harsh climates and high-load conditions, reducing maintenance and replacement frequency.

6. Outstanding Corrosion Resistance

Sunlightweld copper clad steel stranded conductor is engineered with a fully bonded copper coating, providing a durable barrier against moisture, oxidation, and chemical attack. Whether buried in soil, exposed to salt air, or used in humid industrial environments, it maintains its integrity and performance for decades. The uniform copper layer prevents galvanic corrosion, ensuring that the steel core remains protected and the conductor’s conductivity remains stable.

7. Cost Efficiency and Profitability

The Sunlightweld copper clad steel stranded conductor achieves a rare combination of affordability and high performance. Its extended service life, minimal maintenance requirements, and factory-direct cost advantage contribute to exceptional value for infrastructure developers and contractors. By choosing Sunlightweld, customers gain at least 30% higher profit margins compared to other brands, while ensuring uncompromising quality.

8. Custom Engineering and Tailored Solutions

Sunlightweld provides complete customization options — including strand configuration, copper thickness, tensile strength, and surface treatment — to ensure every copper clad steel stranded conductor aligns perfectly with project requirements. Whether for power distribution, lightning protection, or grounding networks, the product can be precisely designed for the intended environment.

9. Dedicated Expert Support

Beyond manufacturing excellence, Sunlightweld's engineering team provides comprehensive technical support, including system design guidance, installation recommendations, and performance analysis. This ensures customers not only receive a superior product but also complete service confidence throughout the project lifecycle.

Sunlightweld: A Global Leader in Earthing and Grounding Systems

As a leading supplier, manufacturer, and factory specializing in earthing materials, grounding products, and lightning protection systems, Sunlightweld is recognized worldwide for its innovation, quality, and value.

Leveraging the efficiency of China's integrated supply chain, Sunlightweld maintains a competitive edge in both production speed and cost control. This means faster delivery times, higher customization flexibility, and the ability to offer factory-direct prices that give clients at least 30% higher profit margins than competitors.

The company's commitment to continuous improvement and global cooperation drives its mission to provide top-quality earthing solutions that meet international standards and exceed customer expectations. Sunlightweld is now actively expanding its global partnership network, inviting distributors, agents, and contractors worldwide to join in shared success.

The Sunlightweld copper clad steel stranded conductor is not just a cable — it is a strategic solution for engineers and businesses seeking unmatched performance, reliability, and cost-effectiveness. By uniting copper's conductivity with steel's strength, Sunlightweld offers a product that meets the highest standards for grounding, lightning protection, and electrical stability.

With IEC & UL certifications, customizable specifications (0.254–0.8 mm), factory-direct pricing, and expert support, Sunlightweld continues to set the benchmark for quality in the global earthing and grounding industry. For every project that demands long-lasting conductivity, mechanical resilience, and unbeatable value, there's only one name you can trust — Sunlightweld copper clad steel stranded conductor, where strength meets conductivity, and performance meets profit.

https://www.sltup.com/Copper-Bonded-Steel-Stranded-Conductor-Factory-Price-and-Supplier.html

www.sltup.com

Sunlightweld

+ There are no comments

Add yours