In the rapidly growing lithium-ion battery industry, the demand for high-performance and reliable batteries has never been higher. One of the critical factors that determine battery efficiency, energy density, and life cycle is the quality of material mixing during production. This is where a Lithium Battery mixer becomes an indispensable piece of equipment.

Designed specifically for battery slurry preparation, Lithium Battery mixers are widely used to blend cathode and anode materials with binders, solvents, and conductive additives to achieve consistent particle dispersion, uniform viscosity, and optimal slurry stability.

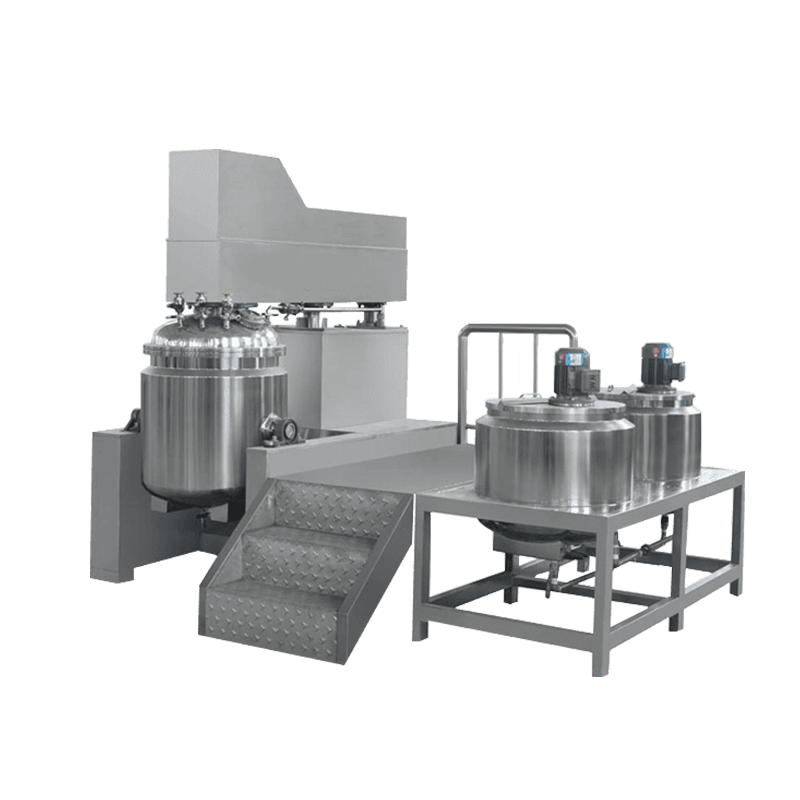

A leading provider of such equipment, Orisun, specializes in the design and manufacturing of advanced mixers for the chemical and materials processing industry. Their mixers are renowned for high precision, robust construction, energy efficiency, and reliability, making them a preferred choice for battery manufacturers, chemical producers, and adhesive formulators.

The Role of Lithium Battery Mixers in Material Processing

The production of lithium-ion batteries requires precise and homogeneous mixing of active materials, which directly impacts the battery’s electrochemical performance. Lithium Battery mixers play a pivotal role in achieving this by:

-

Ensuring even dispersion of powders such as lithium cobalt oxide (LCO), lithium iron phosphate (LFP), or nickel manganese cobalt (NMC) for cathodes.

-

Maintaining uniform slurry viscosity for smooth coating onto current collectors.

-

Reducing agglomeration of conductive additives and binder materials.

-

Enhancing batch-to-batch consistency to ensure high-quality mass production.

Orisun’s Lithium Battery mixers are equipped with precision impellers, high-shear mechanisms, and robust vessel designs that allow for efficient mixing of high-viscosity slurries, which are common in both anode and cathode material formulations.

Advanced Features of Orisun Lithium Battery Mixers

Orisun’s mixers are designed with cutting-edge technology and durability in mind. Key features include:

-

High-shear mixing capability for uniform particle distribution even in high-viscosity slurries.

-

Temperature-controlled jackets to maintain stable material properties and prevent thermal degradation.

-

Digital control systems with adjustable speed, torque, and mixing duration for precise process control.

-

Corrosion- and abrasion-resistant construction suitable for aggressive chemical slurries.

-

Energy-efficient motors that reduce operational costs while providing consistent performance.

-

Easy cleaning and maintenance for uninterrupted production cycles.

These features make Orisun’s Lithium Battery mixers highly versatile, capable of processing not only battery slurries but also sealants, thermally conductive adhesives, structural adhesives, and solder pastes—demonstrating the equipment’s adaptability across the chemical and materials processing industry.

Applications in Cathode and Anode Material Production

Cathode material preparation requires meticulous mixing to ensure that active materials, conductive agents, and binders are fully dispersed. Improper mixing can result in uneven coating, poor electrochemical performance, and shorter battery life. Lithium Battery mixers allow manufacturers to produce homogeneous cathode slurries, which are critical for achieving high energy density and stable cycle performance.

For anode material production, graphite, silicon, and other anode powders are combined with binders and conductive additives. Orisun’s mixers provide high-viscosity handling and precise control, producing smooth, consistent anode slurries that adhere uniformly to current collectors, enhancing battery performance and reducing defects.

Additionally, Orisun’s mixers are widely used in other high-tech chemical processes including adhesives, sealants, thermal conductive pastes, and solder paste production, showing the versatility of their Lithium Battery mixer technology.

Advantages of Partnering with Orisun

Choosing Orisun for your Lithium Battery mixer solutions brings multiple benefits:

-

Superior consistency and quality: High-precision mixing ensures uniform slurry for better electrode performance.

-

Durable and reliable equipment: Resistant to corrosion, abrasion, and high-viscosity materials.

-

Scalable and versatile designs: Suitable for laboratory, pilot, and industrial-scale production.

-

Intelligent control systems: Digital monitoring for speed, torque, and temperature adjustments.

-

Energy-efficient operation: Optimized motor design reduces electricity consumption.

With their focus on innovation, quality, and customer-centric design, Orisun has become a trusted manufacturer for companies producing lithium battery materials, adhesives, and high-performance chemical slurries.

Conclusion

The role of Lithium Battery mixers in cathode and anode material processing cannot be overstated. They ensure uniform dispersion, consistent viscosity, and high-quality slurry production, directly impacting the performance, efficiency, and reliability of lithium-ion batteries.

Orisun’s advanced mixing solutions offer manufacturers a combination of precision engineering, robust construction, and intelligent control systems. Their mixers not only optimize battery slurry preparation but also extend to other chemical processing applications such as adhesives, sealants, and solder pastes.

By incorporating Orisun’s high-performance Lithium Battery mixers into production, manufacturers can achieve superior material quality, operational efficiency, and long-term stability, supporting the next generation of high-performance lithium-ion batteries.

Hydraulic Press Machine Features Explained: From Design to Performance

www.orisunmachinery.com

Orisun

+ There are no comments

Add yours