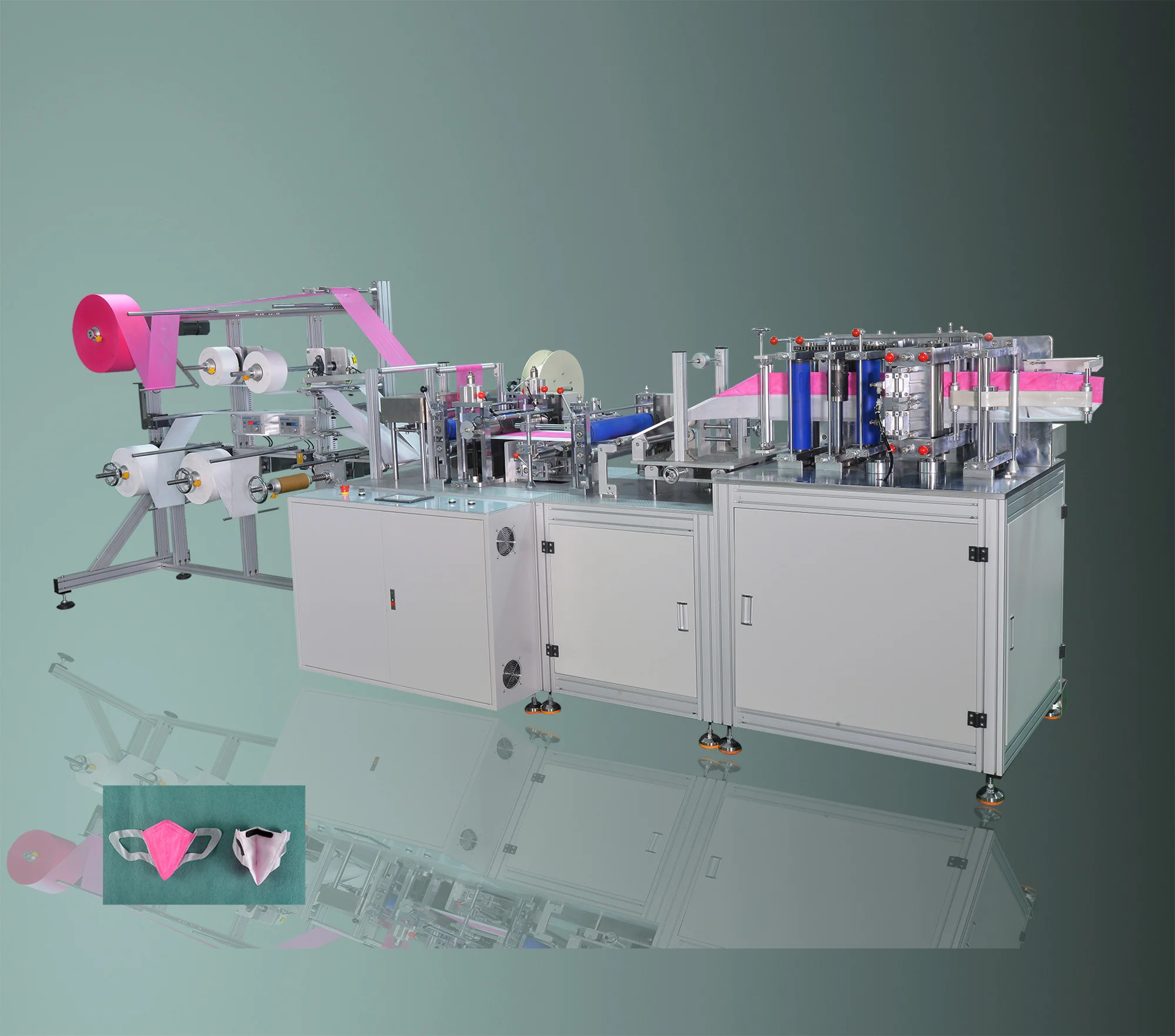

In the wake of increased global demand for protective face masks, folding mask machines have become essential equipment in the medical and personal protective equipment (PPE) industries. These machines automate the complex process of producing pleated masks, ensuring high efficiency, consistent quality, and compliance with safety standards. Broadfair Automation Equipment Co., Ltd., a high-tech enterprise specializing in R&D, production, and sales of automation machinery, offers advanced solutions in folding mask manufacturing that meet the needs of modern production lines.

Understanding Folding Mask Machines

Folding mask machines are specialized equipment designed to manufacture pleated face masks, including surgical masks and other protective coverings. The pleated, or “folded,” design of these masks allows for better fit and coverage, adapting to different face shapes while maximizing filtration area. These machines integrate multiple production steps—such as material feeding, folding, ultrasonic welding, ear loop attachment, and cutting—into a single automated process.

By automating these operations, folding mask machines significantly reduce manual labor, minimize errors, and enhance production speed. Broadfair Automation Equipment Co., Ltd. designs machines that provide seamless integration of each step, delivering a reliable and efficient manufacturing solution.

Key Functions of Folding Mask Machines

Folding mask machines are engineered with multiple advanced functions to ensure both productivity and product quality:

-

Material Feeding and Alignment: The machine accurately feeds nonwoven fabrics, melt-blown layers, and other mask materials, ensuring proper alignment before folding. Precise material handling prevents misalignment that could compromise mask effectiveness.

-

Folding and Pleating Mechanism: The core function of the machine is to create uniform pleats across the mask body. Consistent pleating is essential for maintaining mask coverage, structural integrity, and a professional appearance.

-

Ultrasonic Welding: Ultrasonic technology is used to bond mask layers and attach ear loops without adhesives, maintaining hygiene standards and reducing production time.

-

Cutting and Shaping: The machine cuts masks to precise dimensions, producing uniform products ready for packaging.

-

Automation and Control Systems: Advanced folding mask machines come equipped with intelligent control systems for monitoring production speed, adjusting parameters, and ensuring consistent quality. Broadfair Automation’s machines offer intuitive interfaces and automated fault detection, which minimize downtime and enhance operational efficiency.

Operational Advantages of Folding Mask Machines

Investing in folding mask machines provides several key advantages for manufacturers:

-

High Production Efficiency: Automated machines can produce hundreds or thousands of masks per hour, meeting large-scale demand while maintaining consistent quality.

-

Reduced Labor Costs: Automation minimizes the need for manual labor, freeing staff to focus on quality inspection, maintenance, and other critical tasks.

-

Consistent Quality Control: Machines ensure precise pleating, uniform welding, and accurate cutting, resulting in masks that comply with safety and regulatory standards.

-

Flexibility: Many machines allow for adjustment of mask sizes, pleat depth, and ear loop attachment methods, accommodating different market requirements.

-

Sustainability: Efficient machines reduce material waste, energy consumption, and production errors, supporting more sustainable manufacturing practices.

Broadfair Automation Equipment Co., Ltd. combines advanced engineering with decades of experience in automation to produce folding mask machines that maximize productivity while minimizing operational challenges.

Applications Across Industries

While widely used in medical and PPE manufacturing, folding mask machines are also valuable in other sectors where protective masks are required, such as pharmaceutical, laboratory, and industrial workplaces. Their versatility allows manufacturers to quickly adapt to sudden increases in demand, such as during public health emergencies, while maintaining product quality and safety.

Conclusion

Folding mask machines are indispensable in modern mask production, offering automated solutions that enhance efficiency, quality, and reliability. By integrating material feeding, pleating, welding, and cutting into a single automated process, these machines streamline production while minimizing errors and labor costs. Broadfair Automation Equipment Co., Ltd., with its comprehensive expertise in R&D, production, and sales, delivers high-quality folding mask machines designed to meet the dynamic demands of the protective equipment industry. For manufacturers seeking efficiency, precision, and operational excellence, investing in advanced folding mask machinery is a strategic choice.

Top Features to Look for in a Fish Type Mask Machine for Efficient Mask Production

www.broadfairmachine.com

Broadfair Automation Equipment Co., Ltd.

+ There are no comments

Add yours