As environmental regulations tighten and industries prioritize sustainable practices, dry chemical filter media has emerged as a key solution in industrial filtration. Known for its efficiency in removing acidic gases, heavy metals, VOCs, and odors without the use of water or liquid chemicals, this type of media is increasingly adopted in sectors requiring clean and compliant air emissions.

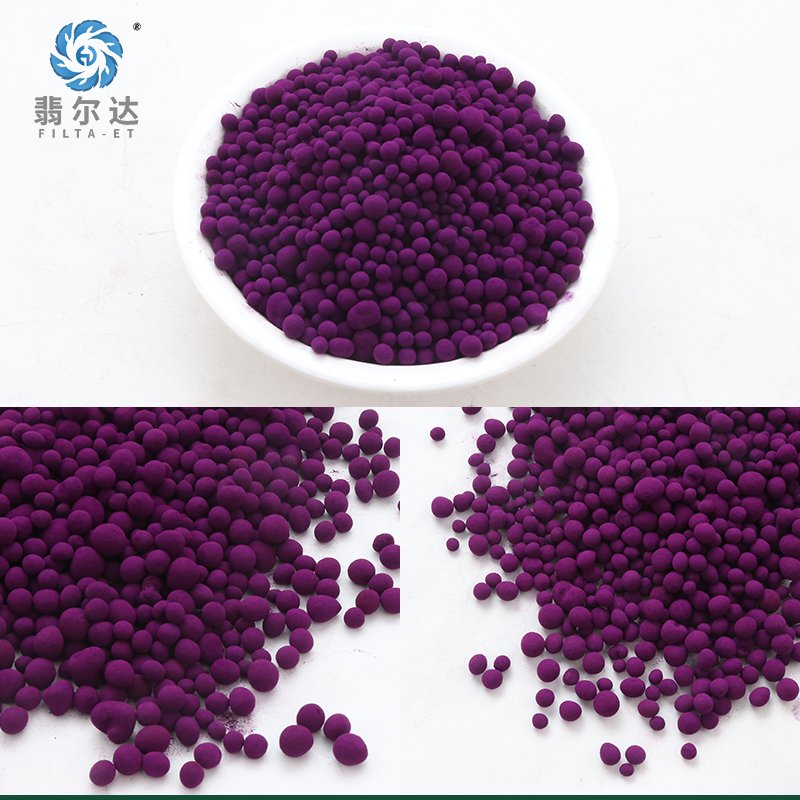

At the center of this advancement is Feierda, a professional company specializing in the research, development, production, and sales of eco-friendly filtration materials. Feierda's dry chemical filter media is engineered to address the specific needs of industries ranging from waste treatment to high-tech manufacturing, supporting cleaner production processes and reduced environmental impact.

Top 7 Applications of Dry Chemical Filter Media

1. Industrial Waste Incineration

Dry chemical media plays a vital role in neutralizing acidic gases such as SO₂, HCl, and HF emitted during waste incineration. The dry filtration process avoids the use of water and reduces sludge formation, making it a cleaner alternative to wet scrubbing.

Feierda’s contribution: Customized formulations that offer high surface area and reactivity, ensuring effective acid gas removal and extended media life.

2. Coal-Fired Power Generation

Coal combustion remains a major source of sulfur dioxide, particulate matter, and toxic heavy metals. Dry sorbent injection (DSI) systems using chemical filter media reduce these emissions efficiently and cost-effectively.

Feierda advantage: Feierda supplies finely calibrated media that enhances dispersion and reactivity, enabling power plants to meet emission targets with lower sorbent consumption.

3. Cement and Lime Production

Cement and lime kilns release complex flue gases that include dust, SOx, NOx, and dioxins. Dry chemical filtration helps control multiple pollutants simultaneously.

Feierda solution: Multi-functional filter media that combines acid neutralization, dioxin adsorption, and dust filtration in a single solution.

4. Steel and Metallurgical Industries

Steel manufacturing and smelting operations release large volumes of acidic gases, heavy metals, and organic compounds. Dry media is ideal for these high-temperature, high-dust environments.

Why Feierda? Feierda offers temperature-resistant filter media with stable chemical properties and high mechanical strength for extreme industrial settings.

5. Glass Manufacturing

The glass industry emits fluorides, lead, and sulfur oxides that require effective treatment. Dry chemical filtration helps maintain clarity in environmental compliance without corroding equipment.

Feierda’s edge: Media engineered for non-corrosive operation, reducing maintenance and increasing plant uptime.

6. Pharmaceutical and Chemical Production

These facilities require filtration of hazardous vapors, acidic gases, and volatile organics. Dry chemical media provides reliable removal without introducing moisture into sensitive environments.

Feierda service: Tailored filtration solutions that meet industry-specific standards for safety, purity, and compliance.

7. Food Processing and Packaging

Processes such as roasting, frying, and packaging generate odors and light VOCs. Dry chemical media removes these pollutants effectively, keeping air clean without affecting product quality.

Feierda assurance: Food-grade, non-toxic filter media suitable for use in food industry environments.

Frequently Asked Questions (FAQ)

Q1: What is dry chemical filter media made of?

A: Dry chemical filter media typically consists of substances like activated alumina, calcium hydroxide, sodium bicarbonate, or modified activated carbon, depending on the target pollutants.

Q2: How does dry chemical filtration differ from wet scrubbers?

A: Unlike wet scrubbers, dry filtration systems do not use water, making them more suitable for arid regions and reducing the complexity of wastewater treatment.

Q3: How long does dry chemical filter media last?

A: Media lifespan varies based on pollutant concentration, operating temperature, and air flow, but Feierda’s high-capacity media can last significantly longer than standard alternatives.

Q4: Is Feierda’s filter media customizable for unique industrial needs?

A: Absolutely. Feierda offers custom formulations and particle sizing to match the requirements of different industries and filtration systems.

Q5: Is dry chemical filter media safe to handle?

A: Yes, when used according to safety guidelines. Feierda provides MSDS documentation and handling instructions with every product to ensure safe usage.

Conclusion

Dry chemical filter media has become a cornerstone of modern industrial air pollution control. Whether in waste management, heavy industry, or clean manufacturing, its waterless operation, high efficiency, and versatility make it an essential tool for cleaner production.With deep expertise and commitment to innovation, Feierda continues to help industries reduce emissions and support global sustainable development goals.

Applications of Exhaust Gas Purification Chemicals Across Different Sectors

www.filta-et.net

Feierda Environmental Technology (Zhenjiang) Co., Ltd.

+ There are no comments

Add yours