As the manufacturing industry rapidly evolves toward digitalization and automation, smart factories are emerging as the new standard for efficiency, flexibility, and intelligence. Central to this transformation are advanced machining systems and intelligent material handling solutions. One such innovation that is redefining precision engineering is the Five-Axis Crane Gantry System.

These systems are playing an increasingly important role in automated production lines, enabling manufacturers to handle complex, heavy, or delicate workpieces with unmatched precision and flexibility. At the forefront of this integration is Zhiquan, a specialized manufacturer and distributor of high-performance CNC machining centers, wire cutting machines, EDM (electrical discharge) forming machines, and milling machines. Zhiquan is committed to delivering next-generation technology to empower smart manufacturing environments.

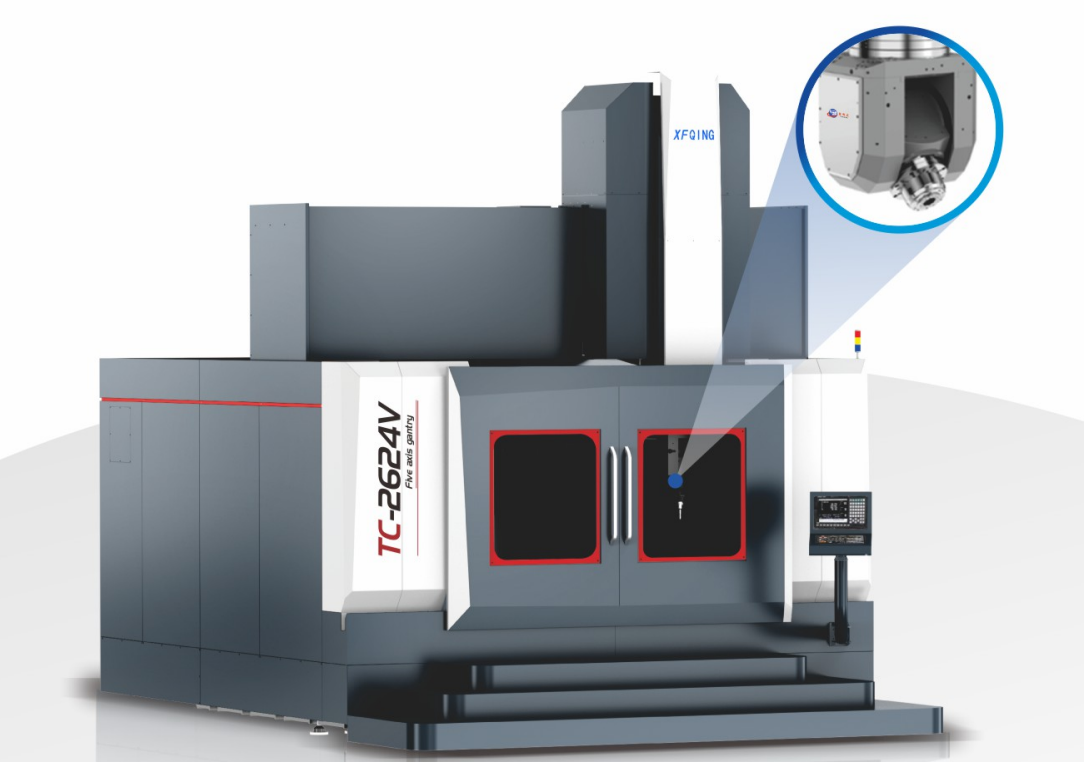

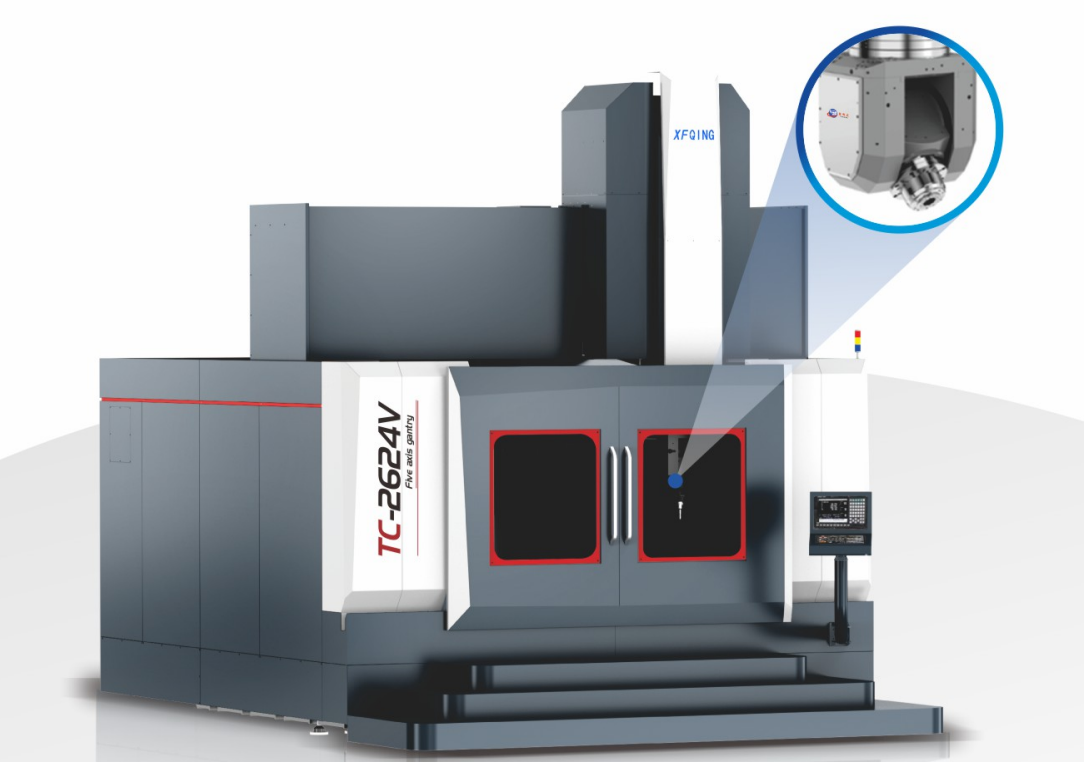

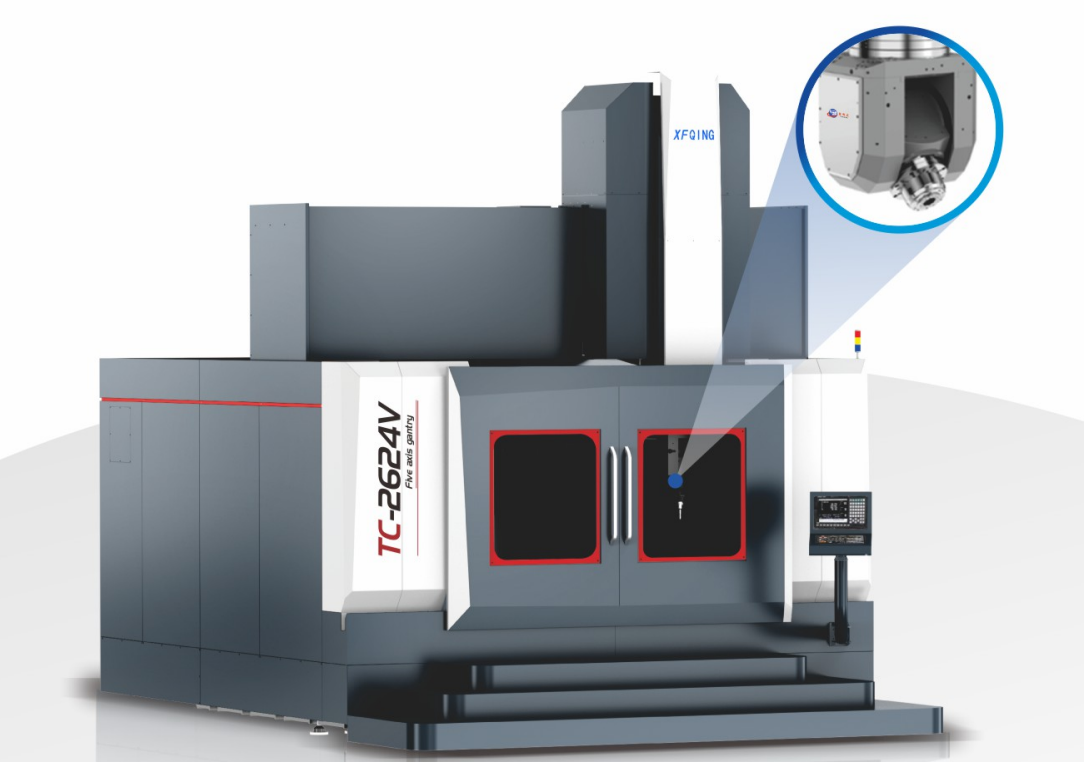

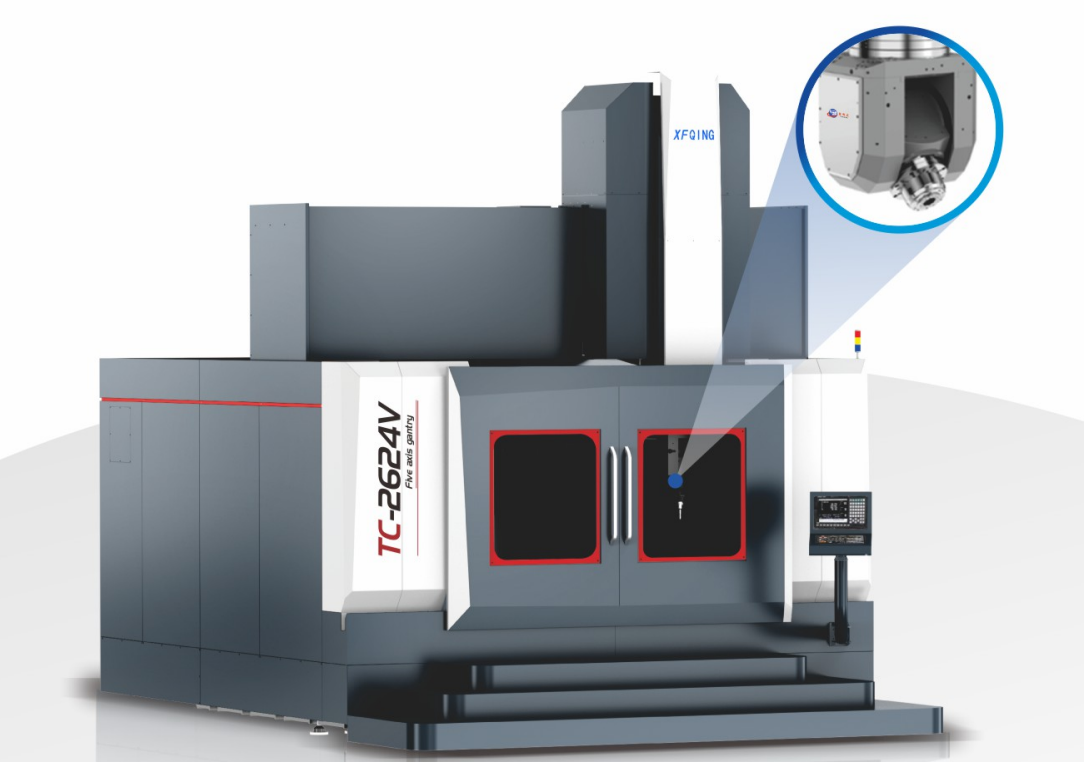

What Is a Five-Axis Crane Gantry?

A Five-Axis Crane Gantry is an overhead robotic system equipped with a multi-directional lifting and positioning mechanism. Unlike traditional gantry cranes, which typically move along three axes (X, Y, Z), five-axis systems offer two additional degrees of motion—rotational and tilting movement—which significantly expand their functional range.

These systems are typically used to:

Load and unload CNC machines or workstations

Transfer precision parts across work cells

Position heavy components with millimeter accuracy

Support automated assembly and inspection processes

By integrating seamlessly with intelligent manufacturing systems, five-axis crane gantries serve as the "muscle and coordination center" in a smart factory.

Key Features and Functions

1. High-Precision Positioning

Thanks to advanced servo motors and real-time control systems, five-axis gantries can position objects with extreme accuracy, even in tight production environments. This level of precision is essential in industries such as aerospace, automotive, mold-making, and electronics, where tolerances are often measured in microns.

2. Multi-Directional Movement

The ability to rotate and tilt components allows for easy orientation during machining or inspection, reducing the need for manual repositioning and minimizing error.

3. Automated Material Handling

Five-axis gantries can autonomously load raw materials into CNC machines, such as those produced by Zhiquan, and retrieve finished parts without operator intervention—enabling true lights-out manufacturing.

4. Heavy Load Capacity

Designed to handle large molds, dies, or castings, these gantries ensure the safe and smooth movement of bulky components that would otherwise require multiple operators or hoists.

5. Integration with Smart Factory Systems

Modern gantries are equipped with sensors, IoT modules, and machine vision, allowing them to communicate with manufacturing execution systems (MES), CNC machines, and quality control systems. This integration ensures real-time coordination and adaptability.

Zhiquan’s Role in Advancing Smart Manufacturing

Zhiquan is a trusted name in China’s machine tool industry, known for its robust lineup of:

CNC machining centers – ideal for high-speed, multi-axis cutting applications

Wire-cutting machines (WEDM) – offering precision for fine molds and complex geometries

EDM forming machines – perfect for high-hardness materials and intricate cavities

Milling machines – combining durability with accuracy for general machining tasks

Zhiquan’s machines are increasingly paired with intelligent automation systems like five-axis gantries to create fully digital, interconnected smart workshops. The synergy between Zhiquan’s equipment and automated handling solutions enhances:

Production efficiency

Machining accuracy

Operational consistency

Labor costs and downtime

Through its dedication to quality and innovation, Zhiquan supports manufacturers on their journey toward Industry 4.0 and beyond.

Applications Across Industries

Five-axis crane gantries integrated with advanced machine tools are used in:

Aerospace – for complex parts with tight tolerances

Automotive – in automated engine block and transmission machining lines

Robotics and electronics – for high-precision component manufacturing

Mold & Die – handling and rotating heavy molds during CNC and EDM processes

General machinery – where large or awkwardly shaped parts require flexible handling

By enabling seamless movement and precise placement of parts, five-axis gantries help ensure process flow continuity and superior product quality.

Conclusion

As factories embrace digital transformation, the integration of advanced material handling systems like five-axis crane gantries is no longer a luxury—it's a necessity. These systems not only maximize productivity and reduce human error, but also pave the way for intelligent, autonomous manufacturing.

With a strong foundation in CNC technology and a commitment to innovation, Zhiquan is perfectly positioned to support manufacturers in upgrading their operations. By combining world-class machine tools with smart gantry systems, Zhiquan helps businesses increase competitiveness, achieve leaner operations, and step confidently into the future of smart manufacturing.

Top Industrial Applications of Five-Axis Crane Gantry Systems

www.szzhiquan.com

Suzhou Zhiquan Electromechanical Equipment Co., Ltd.

+ There are no comments

Add yours