Screen printing has long been a staple in the textile and graphic industries, known for its versatility and ability to produce vibrant, durable prints. However, as technology continues to evolve, so too does the landscape of screen printing. In this article, we will explore the latest advancements in screen printing technology, focusing on innovations that enhance efficiency, quality, and sustainability.

- Digital Hybrid Screen Printing

One of the most significant advancements in screen printing technology is the emergence of digital hybrid systems. These systems combine traditional screen printing with digital printing capabilities, allowing for greater flexibility and efficiency.

Benefits:

- Short Runs and Customization: Digital hybrid systems enable printers to produce short runs with high customization levels without the need for extensive setup. This is particularly beneficial for businesses that require unique designs or limited edition prints.

- Reduced Waste: By integrating digital printing, these systems minimize ink waste and reduce the number of screens needed for each design, making the process more sustainable.

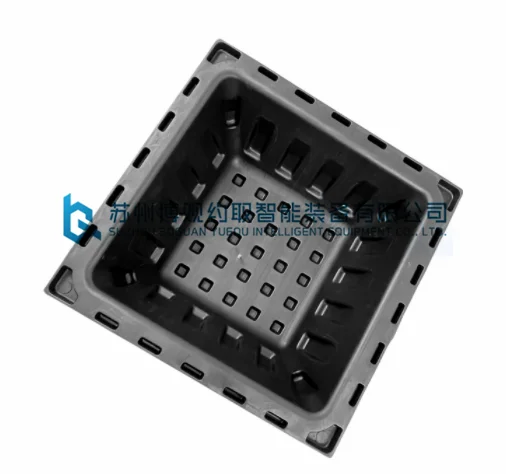

- Automated Screen Printing Machines

Automation is transforming the screen printing industry, with new machines designed to streamline the printing process. Automated screen printing machines can handle multiple colors and complex designs with precision and speed.

Advantages:

- Increased Production Speed: Automated systems can significantly increase production rates, allowing businesses to meet high demand without sacrificing quality.

- Consistency and Accuracy: These machines ensure consistent ink application and registration, reducing the likelihood of errors and enhancing the overall quality of the prints.

- Eco-Friendly Inks and Materials

As sustainability becomes a priority in manufacturing, the screen printing industry is witnessing a shift towards eco-friendly inks and materials. Water-based inks, for instance, are gaining popularity due to their lower environmental impact compared to traditional solvent-based inks.

Key Points:

- Healthier Work Environment: Water-based inks are less toxic, contributing to a safer workplace for employees.

- Biodegradable Options: Many new inks are designed to be biodegradable, aligning with the growing consumer demand for sustainable products.

- Advanced Screen Preparation Techniques

The preparation of screens is a critical step in the screen printing process, and advancements in this area are enhancing efficiency and print quality. New technologies, such as laser engraving and automated screen exposure units, are revolutionizing how screens are prepared.

Highlights:

- Laser Engraving: This technology allows for precise and intricate designs to be etched onto screens, reducing the time and labor involved in traditional methods.

- Automated Exposure Units: These units ensure consistent exposure times and optimal screen quality, leading to sharper images and better color reproduction.

- Integration of Artificial Intelligence (AI)

AI is making its mark in various industries, and screen printing is no exception. The integration of AI in screen printing processes can optimize production workflows and enhance quality control.

Applications:

- Predictive Maintenance: AI can analyze machine performance data to predict when maintenance is needed, reducing downtime and improving operational efficiency.

- Quality Assurance: AI-driven systems can monitor print quality in real-time, identifying defects and ensuring that only the highest quality products reach the market.

Conclusion

The screen printing industry is undergoing a transformation driven by technological advancements that enhance efficiency, quality, and sustainability. From digital hybrid systems to eco-friendly inks and AI integration, these innovations are not only improving the printing process but also aligning with the growing demand for sustainable practices. As businesses continue to adapt to these changes, the future of screen printing looks promising, offering exciting opportunities for creativity and growth in the textile and graphic industries.

+ There are no comments

Add yours