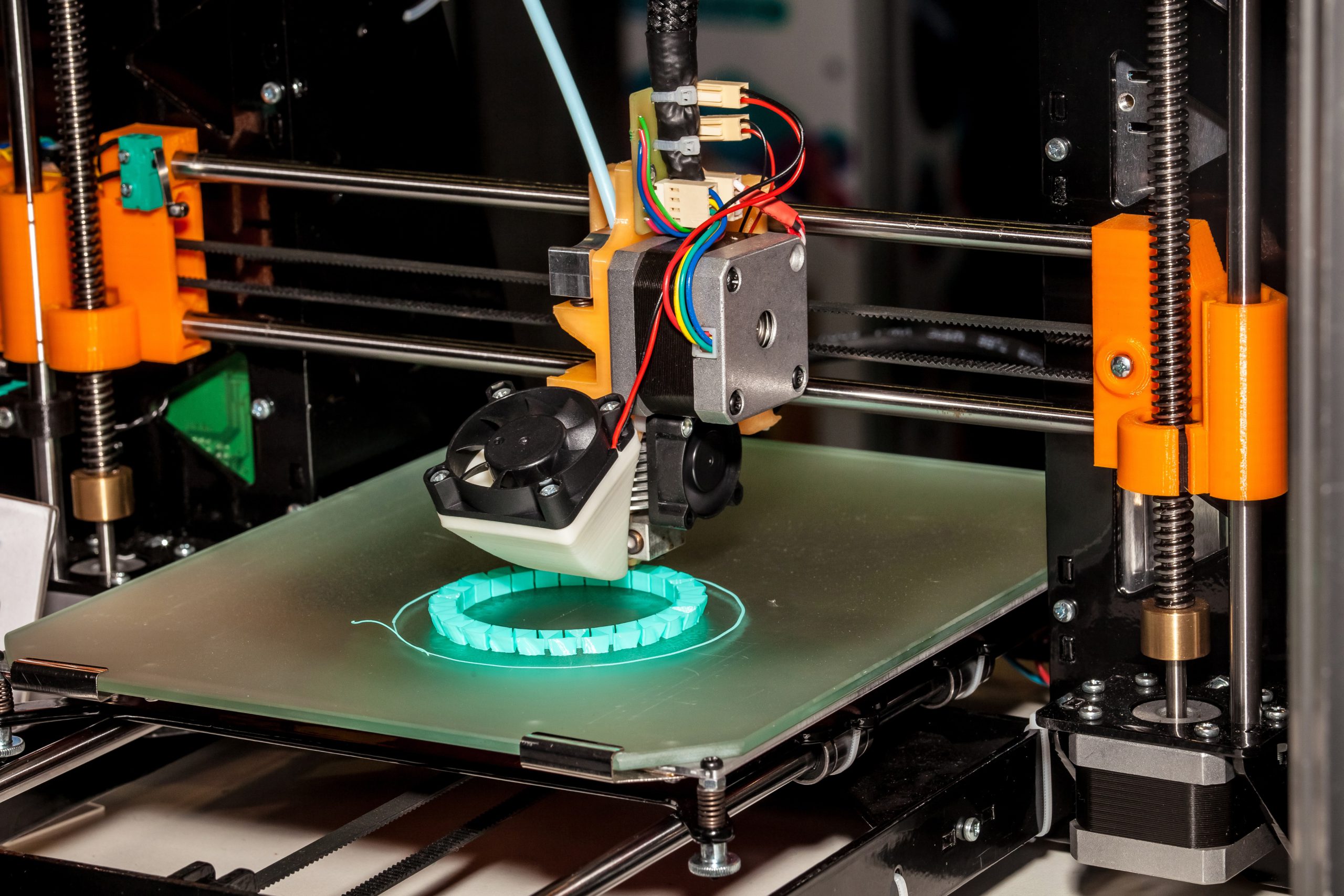

In the realm of additive manufacturing, 3D printing has revolutionized the way we create objects. From intricate prototypes to functional end-use products, the versatility of 3D printing has captured the imagination of industries worldwide. However, one crucial aspect that often remains shrouded in mystery is the cost of 3D printer materials. In this comprehensive guide, we will delve into the intricacies of 3D printer material costs, exploring the factors that influence pricing and providing valuable insights for both professionals and enthusiasts alike.

- Understanding the Basics of 3D Printer Materials:

Before we dive into the cost analysis, it is essential to familiarize ourselves with the various types of 3D printer materials available in the market. From thermoplastics to metals and composites, each material possesses unique characteristics that cater to different applications. We will explore the most commonly used materials, their properties, and their typical price ranges. - Factors Influencing 3D Printer Material Costs:

To comprehend the true cost of 3D printer materials, we must consider the multitude of factors that contribute to pricing variations. This section will discuss key elements such as material type, quality, availability, and market demand. Additionally, we will examine the impact of material specifications, certifications, and regulatory compliance on pricing. - Material Cost Breakdown:

In this section, we will provide an in-depth breakdown of the costs associated with 3D printer materials. We will explore the raw material expenses, including sourcing, processing, and refinement. Furthermore, we will analyze the additional costs incurred during material preparation, such as filament production, powder production, or resin formulation. By understanding these cost components, readers will gain valuable insights into the pricing structure of 3D printer materials. - Market Trends and Price Fluctuations:

The 3D printing industry is dynamic, with market trends and technological advancements constantly shaping the landscape. This section will examine the current market trends and their influence on material costs. We will explore the impact of emerging technologies, market competition, and supply chain dynamics on pricing. By staying informed about the latest trends, readers will be better equipped to make informed decisions regarding material selection and procurement. - Cost Optimization Strategies:

While 3D printer material costs can vary significantly, there are strategies to optimize expenses without compromising quality. This section will provide practical tips and techniques for reducing material costs, including material recycling, waste reduction, and alternative material options. By implementing these strategies, individuals and businesses can maximize their return on investment and achieve cost-effective 3D printing operations.

Conclusion:

In conclusion, understanding the intricacies of 3D printer material costs is crucial for anyone involved in the world of additive manufacturing. By exploring the basics of materials, analyzing the factors influencing pricing, and staying informed about market trends, individuals and businesses can make informed decisions and optimize their 3D printing operations. With this comprehensive guide, we have unveiled the true price of innovation, empowering readers to navigate the world of 3D printer material costs with confidence and efficiency.

+ There are no comments

Add yours