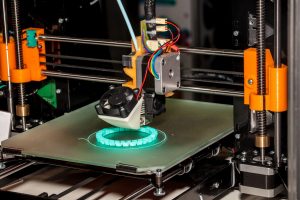

In the realm of additive manufacturing, 3D printing has revolutionized the way we create objects, from intricate prototypes to functional end-use products. While the technology itself has garnered significant attention, one crucial aspect that often remains shrouded in mystery is the cost of 3D printing materials. In this article, we delve into the multifaceted world of 3D printing materials, uncovering their true worth and exploring the factors that influence their pricing.

- Understanding the Spectrum of 3D Printing Materials:

The world of 3D printing materials is diverse, encompassing a wide range of options, each with its unique properties and applications. From thermoplastics like PLA and ABS to high-performance materials such as nylon and carbon fiber composites, the choices are vast. However, the cost of these materials can vary significantly, depending on factors like availability, complexity, and desired characteristics. - Evaluating Material Costs:

Determining the cost of 3D printing materials involves a comprehensive analysis of various elements. Raw material costs, manufacturing processes, quality standards, and market demand all play a role in establishing the price. Additionally, factors like material waste, recycling capabilities, and post-processing requirements can influence the overall cost structure. - Factors Influencing Material Pricing:

a. Material Type and Quality: Different materials have distinct properties, such as strength, flexibility, and heat resistance. These attributes, coupled with the material's source and purity, contribute to its cost.

b. Specialty Materials: Advanced materials like metal powders, ceramics, and biocompatible polymers often command higher prices due to their specialized applications and intricate manufacturing processes.

c. Filament Diameter and Complexity: The diameter of the filament used in 3D printing affects material consumption and cost. Thinner filaments may require more precise extrusion systems, impacting the overall price. Similarly, complex materials with additives or reinforcements can be costlier due to increased production complexity.

d. Market Demand and Availability: Materials with high demand and limited availability may experience price fluctuations. Factors like supply chain disruptions, geopolitical events, and emerging technologies can influence material availability and subsequent pricing. - Cost Optimization Strategies:

To manage the cost of 3D printing materials effectively, several strategies can be employed:

a. Material Selection: Understanding the specific requirements of a project and choosing the most suitable material can help optimize costs without compromising quality.

b. Design Optimization: Reducing material consumption through thoughtful design practices, such as lightweighting and lattice structures, can lead to significant cost savings.

c. Recycling and Reusing: Implementing recycling programs and exploring opportunities for reusing excess or failed prints can minimize material waste and lower expenses.

d. Supplier Relationships: Building strong partnerships with reliable material suppliers can provide access to competitive pricing, bulk discounts, and early knowledge of market trends.

Conclusion:

The cost of 3D printing materials is a multifaceted aspect that requires careful consideration. By understanding the factors influencing material pricing and implementing cost optimization strategies, individuals and businesses can make informed decisions and maximize the value derived from 3D printing technology. As the industry continues to evolve, staying updated on the latest material developments and market trends will be crucial for harnessing the true potential of 3D printing.

+ There are no comments

Add yours